High-efficiency automatic sauce filling production line will not be "lack of weight"

The longest thing we see in our lives is automation and intelligence, whether in modern life or in the online world, because intelligent equipment makes life more changes, and the development of the hot sauce filling production line is the same In this way, how to better produce sauce products, its automated production technology is indispensable. What are the composition and advantages of a fully automatic filling production line?

Composition of automatic chili sauce filling production line:

Automatic disc bottle feeding machine: The bottle unscrambler manually puts the bottles on the circular turntable, and the turntable rotates to continuously transfer the bottles into the conveyor belt and enter the filling machine for filling. Easy to use, low noise, fast unscramble bottle, simple operation is an indispensable link.

Bottle washing machine: It is mainly suitable for cleaning the inside and outside of glass bottles of various shapes. It is washed alternately by two water and one gas (tap water, ionized water, and oil-free compressed air). The bottle can meet the requirements of the production process, and the bottle can be initially blown. Dry function. This machine can be connected or used as a stand-alone machine. This equipment complies with GMP requirements.

Glass bottle dryer: suitable for drying and sterilizing glass bottles and other glass containers, and for baking in food and other industries. The transmission of this machine mainly adopts stainless steel or stainless steel mesh belt and air filtration, which is used for the production of different materials. It can run at an appropriate speed according to different requirements. This electromechanical heating element option uses milky white quartz glass tube as the heating element, which has high coefficient, low energy consumption, heating zone, cooling zone, cooling zone and other areas. The temperature range is 50-300℃. The machine is all made of stainless steel except for the frame. Material production, heat preservation material adopts aluminum silicate fiber, good heat preservation performance and other advantages, it is the choice of pharmaceutical-food-daily chemical industries.

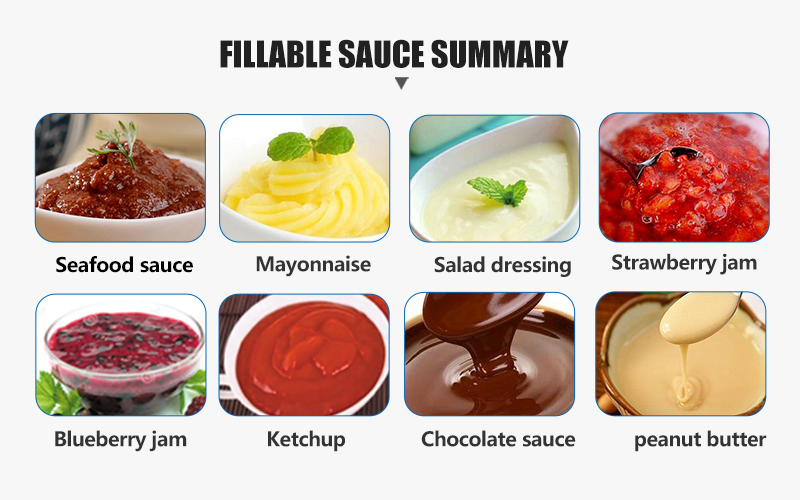

Filling machine: This series of filling machine adopts the principle of piston cylinder drive, which is suitable for filling the thicker sauces such as chili sauce, bean paste, chili sauce, mushroom sauce, etc. with particles in the condiment and high concentration. The filling valve can be customized and enlarged according to customer materials to meet the filling requirements of different customer materials. Equipped with a horizontal mixing hopper, which guarantees to the greatest extent the uniformity of materials and the separation of oil-free sauce during the filling process. The design of this equipment greatly shortens the filling distance from the lower hopper to the filling head, and overcomes the fact that some bottles with high oil content (such as chili oil containing sesame seeds) appear in the filling process. The shortcomings of the filling error of more sauce.

Vacuum capping machine: Abandon the disadvantages of the traditional rotary vacuum capping machine, the developed equipment, the equipment automatically detects that six bottle caps enter the six-head vacuum capping machine, and the capping machine color display will show the screw in real time. The condition of the cap is tested at multiple points of the whole machine. When the inlet has no bottle or cap, the outlet is blocked, the positioning is inaccurate, and the bottle body is dumped, it will automatically stop. The vacuum degree reached by a single capping head can be displayed separately and adjusted separately!

Labeling machine: The whole machine adopts the technology microcomputer-PLC-electronic optical fiber sensor control system, which makes the whole machine run stably and high-speed; the operating system adopts the operation interface control, which is easy to operate, practical and efficient, and has the output counting function; technology The speed is fast and stable; the scope of application is large, and it can be used for labeling round bottles of various sizes; the conveying type rolls the bottle body to make the label adhere more firmly; the front and rear sections can be used in connection.

Advantages of automatic chili sauce filling production line:

The automatic chili sauce filling production line is stable, reliable, and highly automated. Compared with similar products, it has a longer service life, simple maintenance, strong coordination and continuity of the equipment in the entire line, and reasonable design of the entire line. The system structure adopted by the filling equipment meets the needs of mass production and integrated production.

Now the chili sauce filling production line has achieved automated production. The chili sauce filling production line can better target various sauce products, improve the production efficiency of the manufacturer, increase the manufacturer’s income, save labor, and make the chili sauce better. The filling production line better meets the needs of enterprises, so as to achieve technological innovation and better follow the needs of the times.