Oil Packing Machine

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

Oil Packing Machine It has the characteristics of good stability, convenient operation, high cost performance and high degree of automation.

Oil Packing Machine Compared with similar products, the service life is longer, the capacity is more complete, the whole machine design is reasonable.

Oil Packing Machine Perfume oil filling machine is equipped with photoelectric complete interlock device, only need 1-2 people to operate.

Oil Packing Machine The technologies used are today's industry leaders.The whole filling equipment can meet the needs of production, unattended and comprehensive production.

Oil Packing Machine

Oil Packing Machine-Product description:

Oil Packing Machine is suitable for bottled and barrel oil, such as peony seed oil, rapeseed oil, peanut oil, soybean oil, Perilla oil, palm oil and so on.

Oil Packing Machine-Product details:

Oil Packing Machine is also called the conventional barrel edible oil filling machine, using the principle of quantitative flow meter.

The equipment has simple and beautiful appearance, convenient filling capacity adjustment and high filling accuracy.

The whole machine is made of 201 stainless steel, and the part in contact with liquid is made of 304 stainless steel.

Excellent manufacturing process to maintain its outstanding quality and durable and stable performance.

Oil Packing Machine-Product parameters:

1. Power: about 4.0-4.5kw

2. Voltage: AC380V/50Hz

3. Filling capacity range: 500ml-5l

4. Filling efficiency: 2500-3000 bottles/hour (5L hours)

5. Filling accuracy: ≤±0.5-1%ml (5L)

6. Overall weight: about 700Kg

7. Range of compatible bottle height: 260-350mm

8, bottle type compatible with the width or diameter range: 60-150 - mm or Φ 60-150 mm Φ

9 bottle type, compatible with smaller diameter (inside diameter) : 26 mm Φ (other diameter can be customized)

10. Overall dimension: 1700*1300*2100mm (length * width * height)

11. Working direction: left in, right out or right in, left out (optional)

Oil Packing Machine-Product details picture and description:

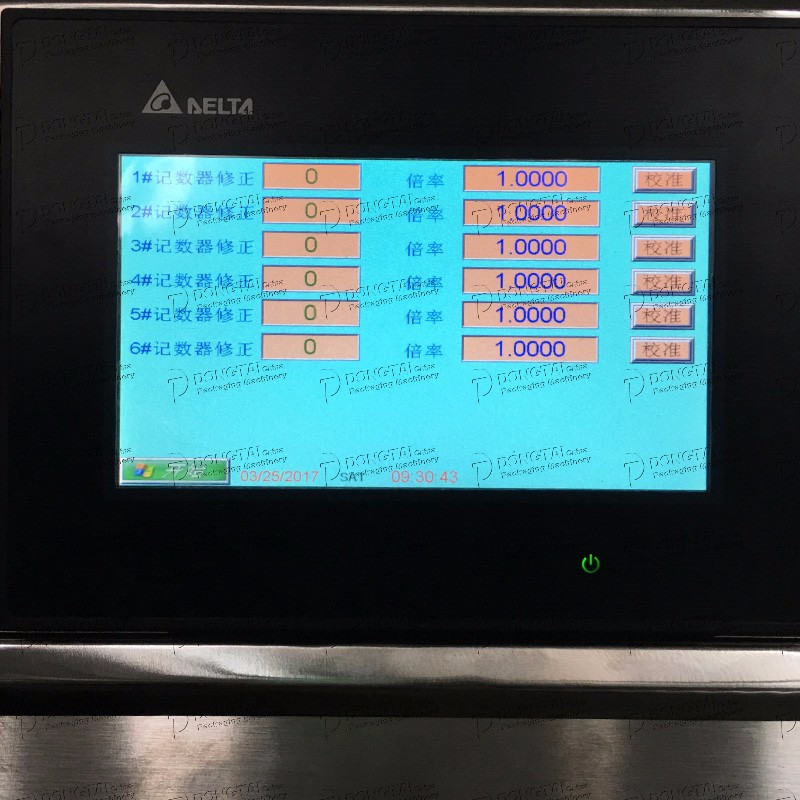

Touch screen with tilt Angle

PLC control touch screen Chinese display interface, can store more than 20 groups of formula parameters, parameters can be preset storage, one-click adjustment completed.

Stand on the top of the machine at an Angle of 30° for clearer observation.

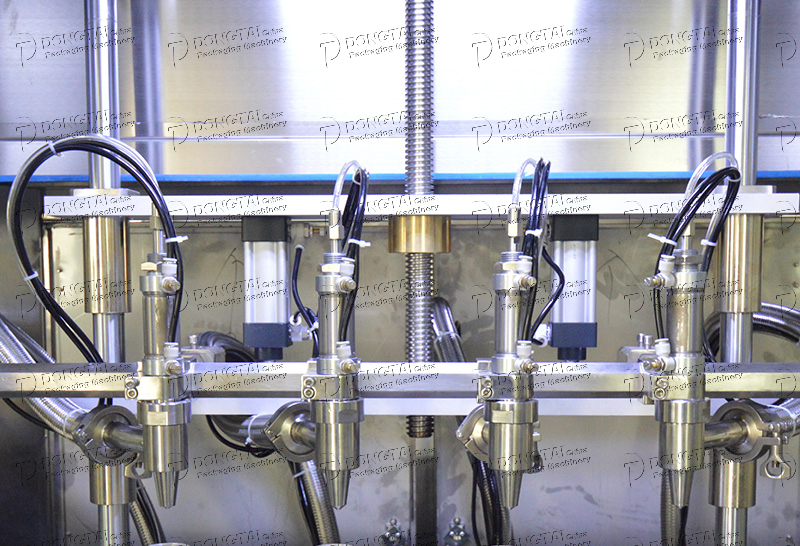

Vacuum back suction drip - proof filling head

The filling head adopts the patent design of utility model certified by the state intellectual property office

The air suction system ensures that there is no leakage during the filling process and no pollution to the conveying chain plate

And bottles.

Diving with multi-stage filling

Filling can be done within the barrel mouth about 5-8mm, patented cutting mouth design, anti-splash: with multi-stage fast and slow filling, it can guarantee full speed filling at high speed.

It can also effectively solve the foam overflow bottle phenomenon when the pump pressure is too high and filling fast.

Ultraviolet sterilizing lamp

Ultraviolet radiation can play the role of sterilization, ensure oil products from pollution, health and hygiene

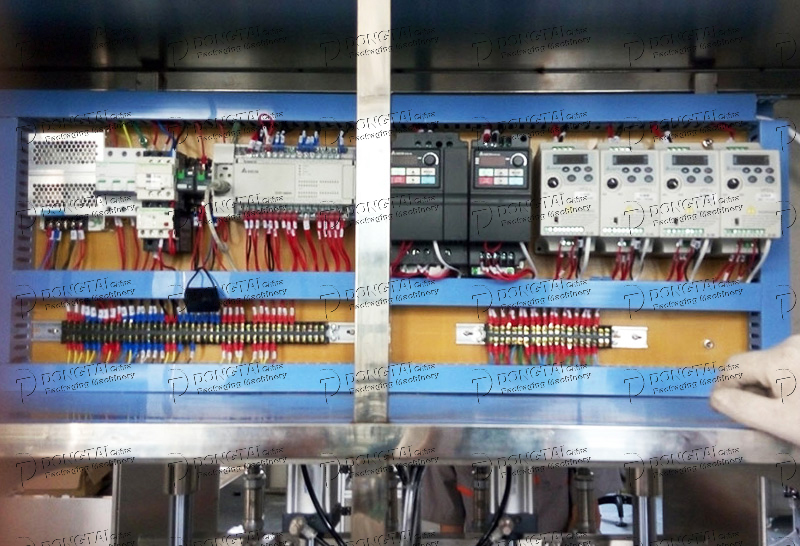

Well-known electrical components

Electricity, gas main parts are used to support imported quality components are well-known at home and abroad

Brand FESTO/SIEMENS/MITSUBISHI/AIRTAC, domestic first-class brand

Agent direct supply, low failure rate, stable and reliable performance, long service life.

Single head single pump single frequency conversion

Volume and metering are freely converted.Each pump is separately controlled

System, and a single inverter speed regulation.;Single head single pump single frequency conversion mode guarantees 1%

Filling accuracy, increased by 20%-35% filling speed.

Meter type measurement

The traditional calculation method of the flowmeter is to send signals through the transmitter, through our company's

Improved, to rotate the encoder to send out the signal, rotating the encoder to send out the pulse signal

It is several times higher, the accuracy is more accurate, and the failure rate is lower, the maintenance is more convenient.

Equipment selection

The shell is made of SUS304 stainless steel, and all materials are 316

(L) stainless steel, in line with GMP standards.

Oil Packing Machine-The finished product to show: