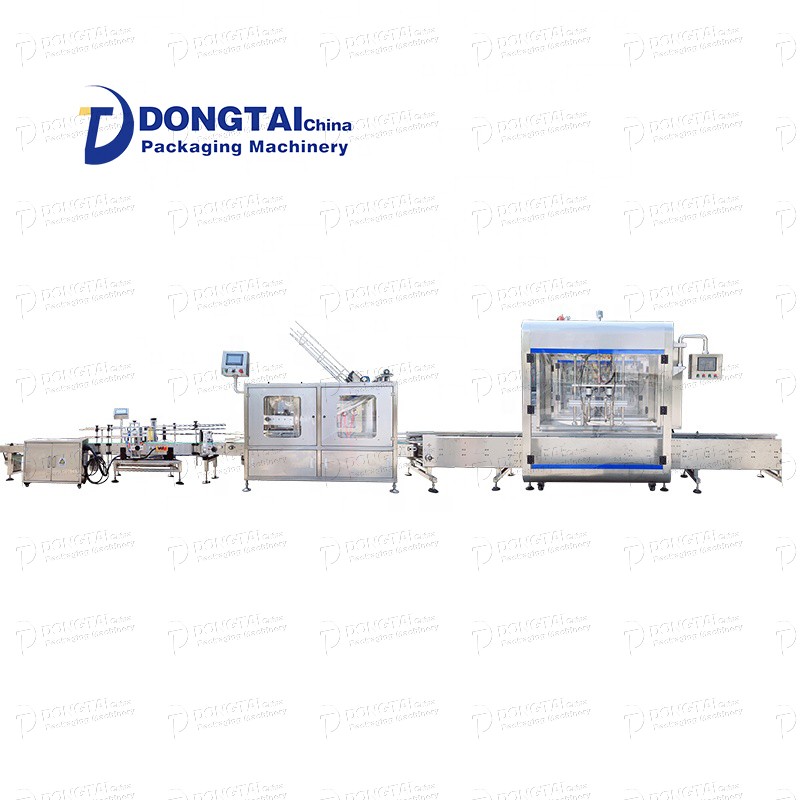

8-head hand sanitizer oil filling line and auto lubricating oil filling line

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

Filling line process

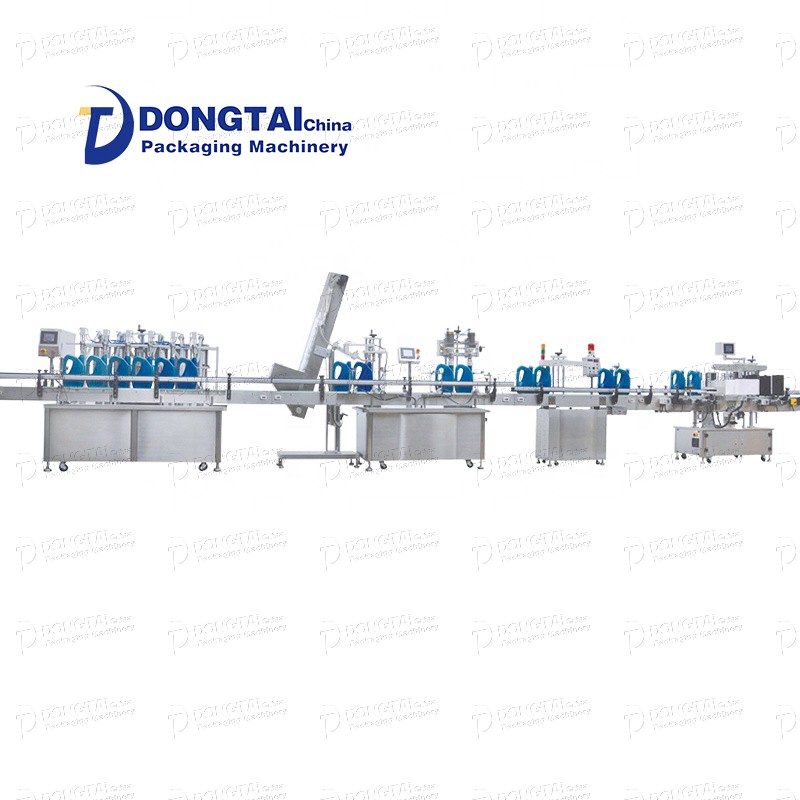

1. Oil filling production line: manually place the bottle on the conveyor belt-filling machine can fill the container-cover (with pump head or nozzle manual

Top cover, if no, the machine top cover)-machine for screwing-automatic round bottle labeling machine for labeling-sorting platform (manual packing)

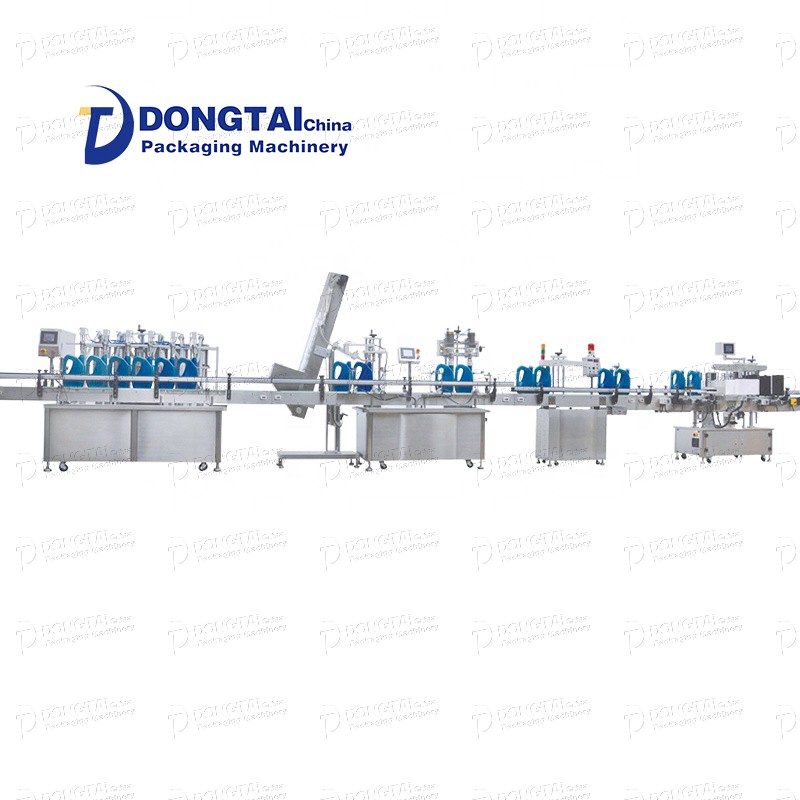

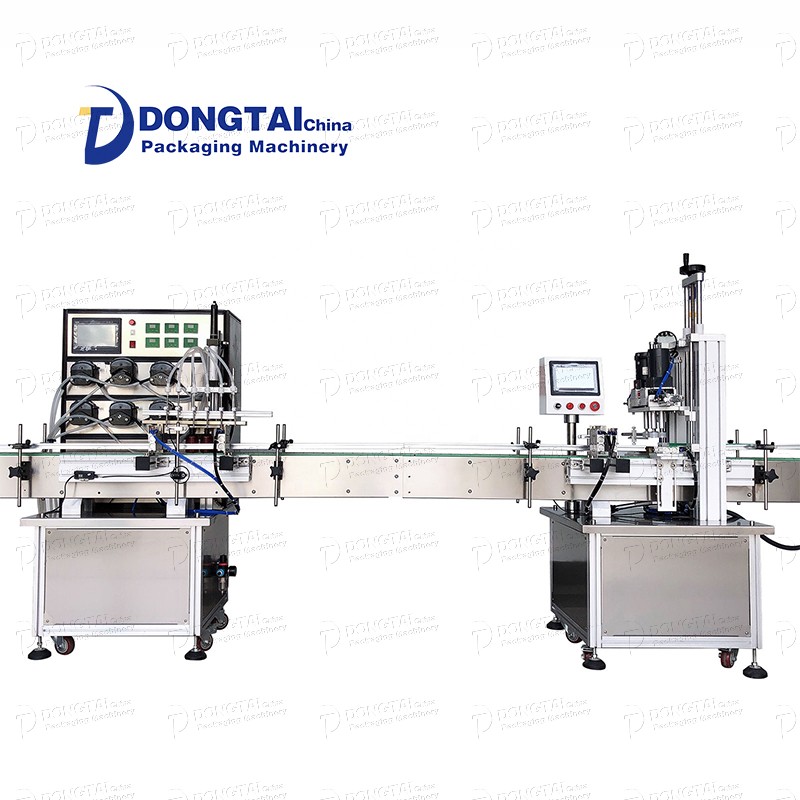

2. Hand sanitizer filling line: 1.5l: manually place the bottle on the conveyor belt-filling machine can fill the container-cover (with pump head or nozzle manual

Top cover, if no, the machine top cover)-machine for screwing-automatic round bottle labeling machine for labeling-sorting platform (manual packing)

8-head hand sanitizer oil filling line and auto lubricating oil filling line

The filling line is automatically stable and reliable, with a high degree of automation, longer continuity than similar products, simple maintenance of the whole line, strong coordination of all equipment in the whole line, good consistency, reasonable and reasonable design. The manufacturing and filling line is driven by a servo motor. The entire packaging process of the 8-head hand sanitizer oil filling line is environmentally friendly, higher and safer. This production line has been well received by customers at home and abroad.

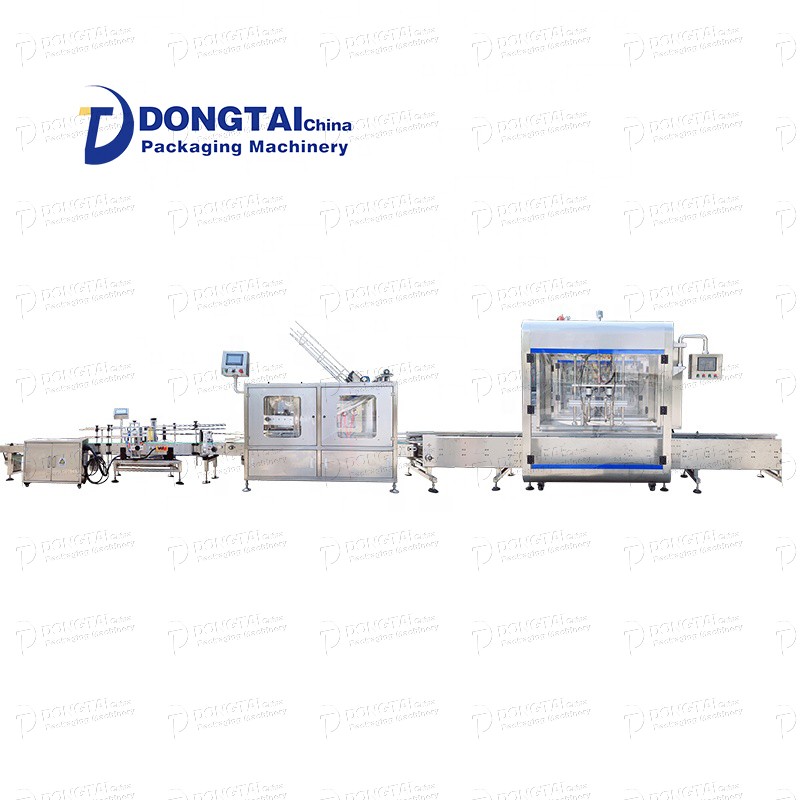

Product introduction of filling and filling automotive lubricant line:

This machine is a lubricating oil filling line designed according to the characteristics of lubricating oil. The machine is compact and reasonable in design, simple and beautiful in appearance, easy to adjust the filling volume, and high in accuracy. It is based on the filling process control technology and imported color touch screen. The machine interface, the filling process realizes one-key operation, and the performance is stable. Two 316 oil storage tanks are used to solve the problem of large filling volume. One oil inlet controls the liquid level of two oil tanks, and one oil storage tank controls 8 filling heads respectively, which is faster and more precise.

The hand sanitizer filling production line equipment integrates light, electricity, and gas. It is controlled by PLC and man-machine interface (touch screen). The actions from bottle feeding, positioning, filling, and bottle out are all fully automated. Direct-flow filling is adopted, and the parts in contact with materials are made of excellent stainless steel and food-grade materials, which meets food hygiene requirements; high automation, stable performance, fast production speed, accurate filling, simple operation, convenient adjustment, and strong adaptability Features.

The hand sanitizer filling production line equipment integrates light, electricity, and gas. It is controlled by PLC and man-machine interface (touch screen). The actions from bottle feeding, positioning, filling, and bottle out are all fully automated. Direct-flow filling is adopted, and the parts in contact with materials are made of excellent stainless steel and food-grade materials, which meets food hygiene requirements; high automation, stable performance, fast production speed, accurate filling, simple operation, convenient adjustment, and strong adaptability Features.