Automatic bottled liquid filling machineAutomatic eye drops aseptic liquid filling machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

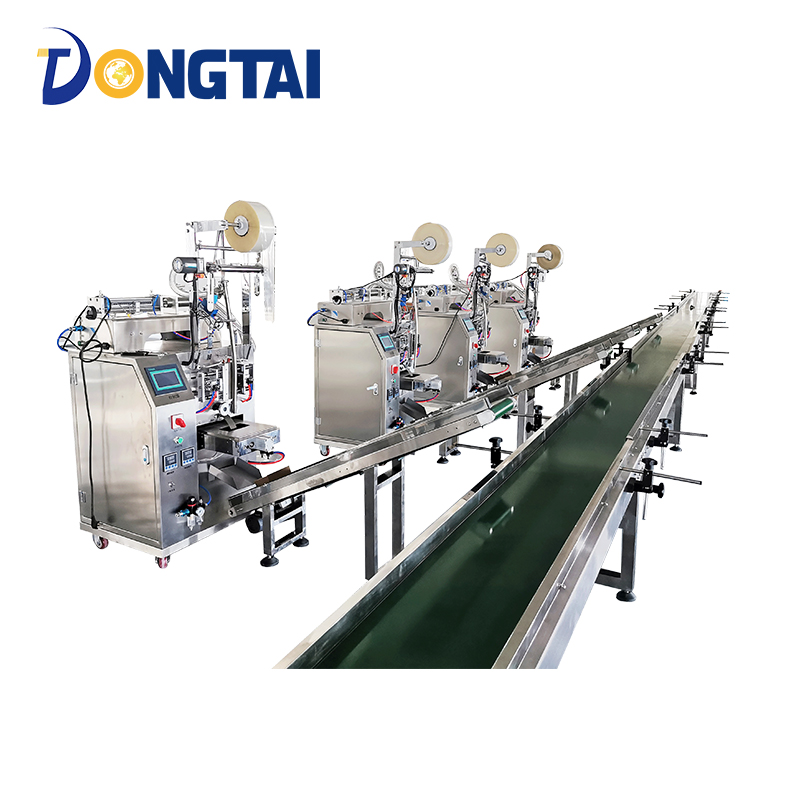

This machine can be used for liquid filling of liquor, milk, sachet liquid, shampoo shampoo, liquid chocolate, liquid soap, eye wash, disinfectant, pesticide, oral liquid, perfume and other industries.

Automatic bottled liquid filling machineAutomatic eye drops aseptic liquid filling machine

product description

The automatic liquid filling machine is an improved design based on the filling machine series products of Xunjie Machinery, and some additional functions have been added. Make the product easier and more convenient in terms of operation, accuracy error, installation adjustment, equipment cleaning, maintenance and so on. The automatic filling machine has the domestic leading filling technology, excellent craftsmanship and brand-new design concept, which makes the filling machine win a good market in the development of the overall packaging machinery industry. For domestic filling machines The development of the industry has greatly promoted.

parameter

| Filling volume | 25-250ml、50-500ml、500-5000ml |

| Filling accuracy | ≦±1﹪ |

| Material viscosity | ≤7000cp |

| Air source | 0.4-0.6MPa |

| Power supply | 380/220V |

| Bottle type | Glass bottle |

| Control | PLC+ Touch Screen |

| Power | 500W |

Equipment advantages

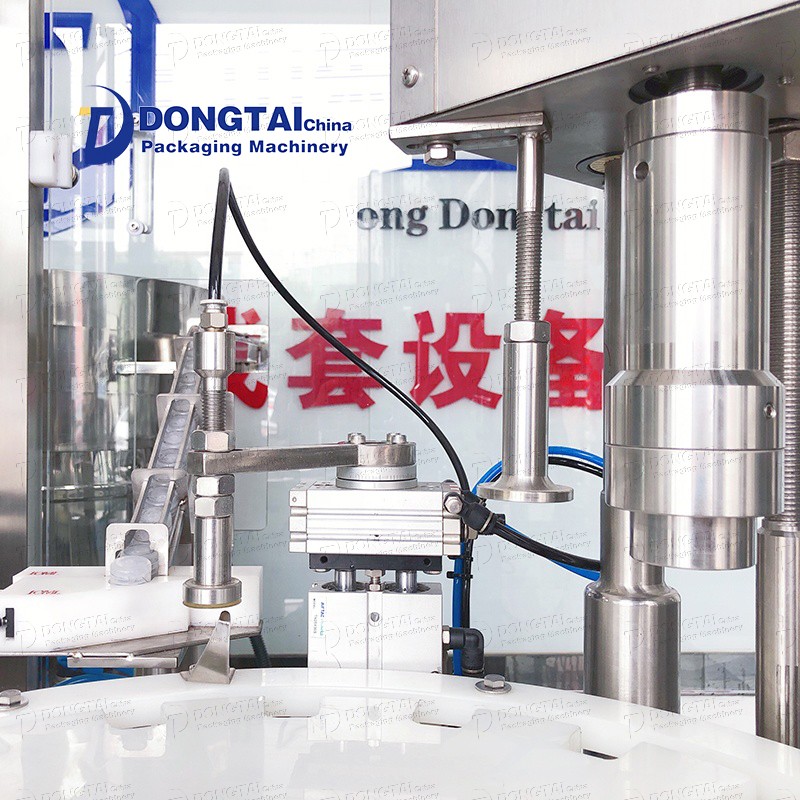

A. The automatic filling machine integrates light, electricity, gas and PLC microcomputer control, and the actions from positioning, filling, and discharging of bottles are completed automatically.

B. It adopts linear normal pressure structure, realizes different measurement by setting the filling time, replaces containers of different shapes, and adjusts different filling volumes without replacing parts, which is simple and convenient!

B. It adopts linear normal pressure structure, realizes different measurement by setting the filling time, replaces containers of different shapes, and adjusts different filling volumes without replacing parts, which is simple and convenient!

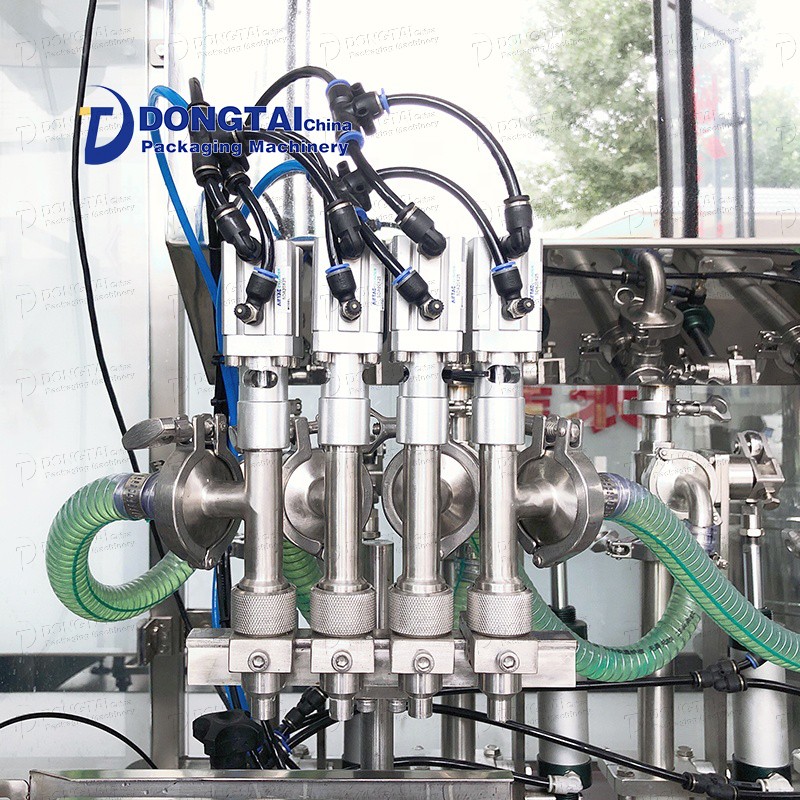

C. The parts in contact with the materials are made of 304 or 316L stainless steel and special corrosion-resistant materials. The unique filling head ensures that there is no dripping during filling.

C. The parts in contact with the materials are made of 304 or 316L stainless steel and special corrosion-resistant materials. The unique filling head ensures that there is no dripping during filling.

D. It has the characteristics of high degree of automation, stable and reliable performance, fast production speed, accurate filling, simple operation and strong adaptability.

D. It has the characteristics of high degree of automation, stable and reliable performance, fast production speed, accurate filling, simple operation and strong adaptability.

Company Information

Company Information