Automatic Cooking Filling Machine

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

Features of Automatic Cooking Filling Machine:

1. The contact parts of materials are made of 316 stainless steel, meeting GMP requirements.

2. The Filling head of Automatic Cooking Filling Machine adopts anti-drip Filling device.

3. Pneumatic components are controlled by PLC (German FESTO) and AirTac (Taiwan) with touch screen Settings.

4. Automatic Cooking Filling Machine seals are made of silicone rubber (resistant to wear, high temperature, acid and alkali, corrosion) and fluororubber (resistant to wear, strong acid and alkali, corrosion).

5. This device can remove the long leather tube from the outlet and move the filling at will, which can meet the unlimited (arbitrarily adjustable) filling capacity requirements of more than 1ml.

6. The liquid filling machine is not limited by the filling equipment and is a reliable and durable liquid filling machine.

Automatic Cooking Filling Machine

Automatic Cooking Filling Machine-Product description:

Automatic Cooking Filling Machine is suitable for weighing and Filling liquids of 5kg to 30kg.

Automatic Cooking Filling Machine is an ideal packing Machine for food, medicine, cosmetics, fine chemicals and other industries, especially suitable for quantitative Filling of edible oil and lubricating oil.This machine adopts PLC to realize high-speed industrial control configuration software.

Automatic Cooking Filling Machine time monitoring, easy to use, easy to adjust.

Automatic Cooking Filling Machine can also automatically complete a series of operations, such as recording into bottles, Filling by weight, and exporting bottles.The Machine is made according to GMP standards.

Each pipe connection is made by quick assembly for easy disassembly and cleaning.The parts in contact with materials and exposed parts are made of high quality stainless steel.

Automatic Cooking Filling Machine is safe

Automatic Cooking Filling Machine-Product details:

(1) the filling head is opened in front of the power source, with small impact force and can avoid splashing;

(2) automatic detection of barrel weight, if the tare weight of the barrel is higher or lower than the built-in parameters, it is regarded as inorganic barrel.

No drums and automatic identification of filling stops and starts.If there are not enough buckets or no buckets in the middle, the machine will automatically identify and not fill the position without buckets.

(3) the system has memory function, after suspension, the filling part can be opened again to continue the previous work, continuous counting;

(4) except the first group, there was no barrel feeding time.The capacity is 1350 barrels per hour and the filling time per group is 16 seconds.(filling machine has 6 filling heads, frequency of frequency converter is 25 Hz)

(5) the filling weight can be continuously monitored on the touch screen;

Can track and record the whole filling process,

You can see the filling weight of the previous group

Automatic Cooking Filling Machine-Product parameters:

| Filling head | 6 |

| Filling volume | 5-30kg |

| Capacity | 500-1600 barrels /H (5KG);400-560 barrels /H (30KG) |

| Filling accuracy | ±0.1% |

| Voltage | 220V, 50Hz |

| Power | 3KW |

| Air source | 1. 0.55-0.65MPa |

| Size | 2200mm*1350mm*1820mm |

| Bottle type | Customized |

| Diameter of bung hole | Customized |

Automatic Cooking Filling Machine-Product details pictures and instructions:

1. Upgrade the appearance of equipment

Before and after use of tempered glass;Simple appearance, strong sense of technology

2. Upgrade of equipment structure

(1) single head, single pump, single structure, centrifugal pump feeding structure, high precision, fast speed (fast feeding), multistage acceleration.On the premise of ensuring the filling accuracy, increase the filling speed by 20% and increase the filling speed by 20%.Buffer tanks are installed in the equipment to avoid large filling errors caused by uneven pipeline pressure.

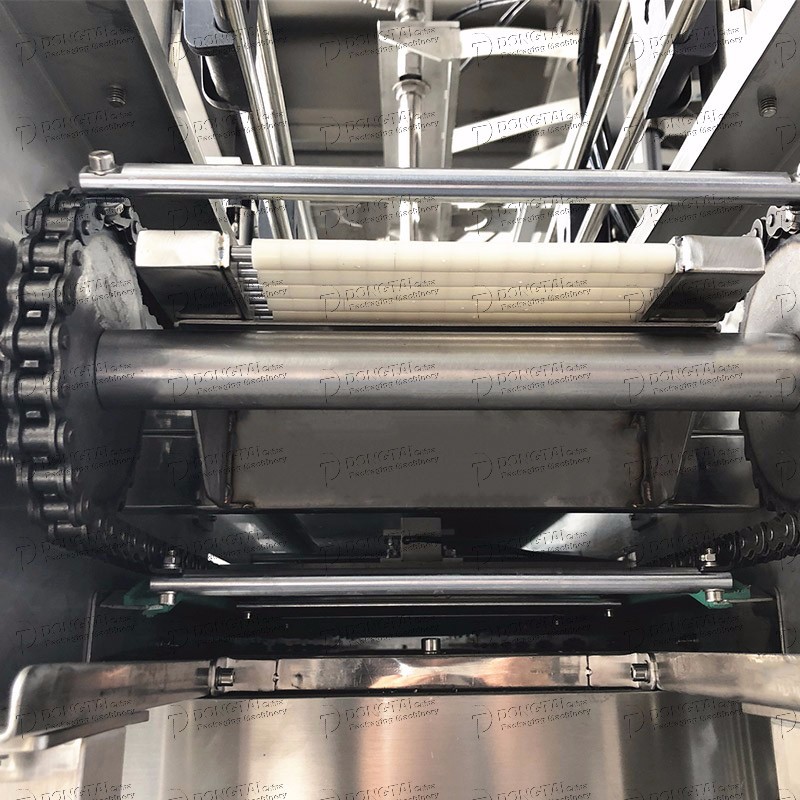

(2) c hain conveyor is suitable for all kinds of bottle filling.

The transmission chain USES teflon rollers for less friction and greater stability, which can extend the service life of the equipment.

Add bottle mouth clamping device: small container filling is more convenient, filling head and bottle mouth positioning is more accurate;

O-type baffle is used to screen the disadvantages of the tensioning wheel (fish-eye is used to adjust the tightness of the sprocket wheel).

Transportation adopts teflon roller type, container transportation is more stable and can be transported before and after

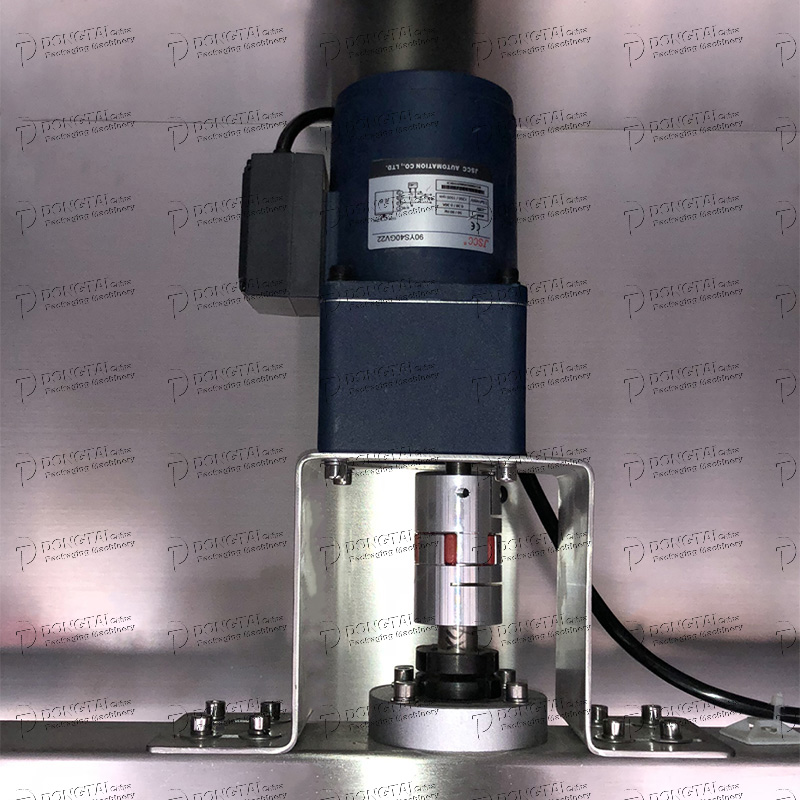

(3) use the listed motor to adjust the height of filling head.Use a button to adjust the height of the touch screen.

The lifting structure and miotor are directly coupled by 90 degrees, thereby reducing friction, reducing power, and saving electrical connections.

(4) the filling head adopts corner seat valve type and the filling plug adopts ptfe sealing ring to prevent corrosion of special materials;

Submersible filling method, defoaming, suitable for filling foaming liquid.

(5) a variety of weighing modules and weighing sensors are adopted, with the error as small as 0.3%

Automatic Cooking Filling Machine Operation method :

Preset parameters → manual barrel setting → automatic filling → manual lid setting → automatic gland setting

Automatic Cooking Filling Machine Pre-sale service:

Design manufacturing process for customers → tailor filling machines and other equipment according to customers' actual production needs → the company can send technicians to the site to plan and design production lines for customers

Automatic Cooking Filling Machine After-sales service:

The company provides free training of production technicians for customers → the company sends technicians to the site to know the installation and debugging of customers → the company provides the vulnerable parts of machinery and equipment throughout the year → the company provides perfect after-sales service to timely solve all technical problems in the operation of customers' equipment → all machines and equipment are guaranteed for one year free of charge.

Automatic Cooking Filling Machine-The finished product to show: