Automatic Engine Oil Filling Machine

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

Automatic Engine Oil Filling Machine has the characteristics of stability, easy operation, high cost performance and high degree of automation.

Compared with similar products, Automatic Engine Oil Filling Machine has longer service life, more complete capabilities and reasonable design of the whole Filling Machine.

Automatic Engine Oil Filling Machine is equipped with coordinated photoelectric and full-line interlocking devices, and only 1-2 operators are required for the Filling Machine.

The technology employed by Automatic Engine Oil Filling machines is an industry leader today.The whole filling equipment meets the needs of production, unmanned and comprehensive production.

Automatic Engine Oil Filling Machine

Automatic Engine Oil Filling Machine-The product description:

Automatic Engine Oil Filling Machine adopts the metering Filling principle of flow meter, with multiple patent certifications, which is suitable for Filling with various specifications (1-5 liters).

Automatic Engine Oil Filling Machine adopts high-precision rotary encoder for measurement to ensure 1% Filling accuracy.

While guaranteeing the Filling accuracy, it increases the Filling speed by 20%-35%, with simple operation, convenient maintenance, labor cost saving and higher production efficiency.

Automatic Engine Oil Filling Machine-Product details:

1. Automatic Engine Oil Filling Machine 316l stainless steel refined anti-drip filling head, specially designed for the filling of edible oil, through good, inside and outside fine throwing, the real food grade.

2. Link the material storage tank to inject the material storage tank through the feed port through power.

3. The air pipe and material pipe are color-separated, convenient for maintenance and replacement. The black air pipe and white vacuum return straw are used.

4. The material receiving trough is installed to prevent the material spilling on the floor and cleaning trouble during debugging or failure.

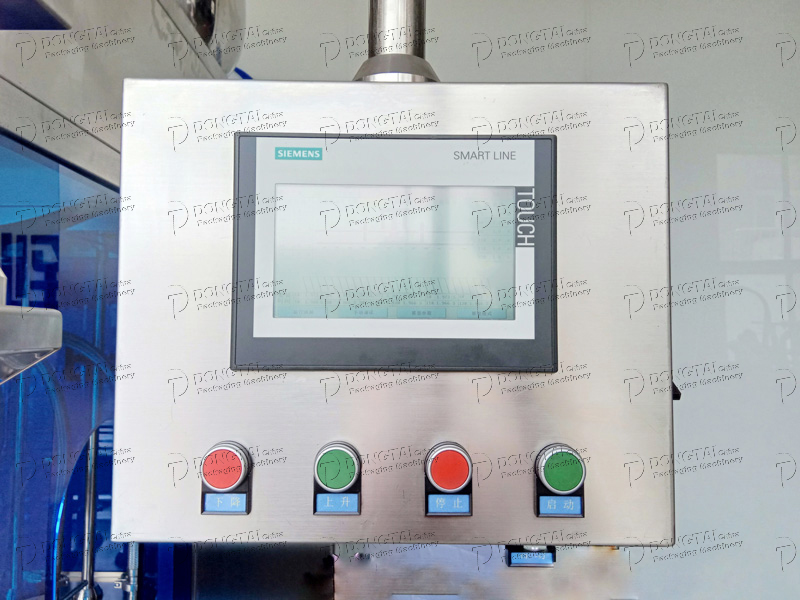

5. Automatic Engine Oil Filling Machine Electronic control module, all controls are controlled by software programming, easy to maintain.

6. Human-machine interface, through intelligent system to control machine parameters and adjust the operation of the machine.

7. Automatic Engine Oil Filling Machine Food grade 304 stainless steel body, in line with national food hygiene standards.

8. Variable frequency power is separated, and the conveyor belt is buffered when starting and stopping to ensure smooth transportation and prevent pouring and splashing.

Automatic Engine Oil Filling Machine-Product parameters:

| The product name | Automatic Engine Oil Filling Machine |

| The filling capacity | 1L-5L |

| The filling speed | 1800-2200Bottle/hour (5L) |

| Filling accuracy | ±0.1% |

| current | 3A |

| The power supply | 380V 50/60HZ |

| power | 2.5KW |

| Air pressure | 0.5-0.7MPA |

| The equipment size | 2450*1750*2400MM(Refer to the size) |

Automatic Engine Oil Filling Machine-Product details picture and description:

Automatic Engine Oil Filling Machine Strong maneuverability (one head one pump, separate control, single frequency

converter speed regulation, overcoming the problem of uneven flow)

High speed filling(one single filling head one power, matching the filling speed

according to the pipe diameter flow rate, increasing the filling speed by 20%0-30%

A High precision(single pump head independent control, constant pressure, more

stable flow rate, single head even can modify the error directly which ensuring

1% filling accuracy

Stable work performance( when a pipeline of a certain station is blocked, it will not

affect other stations and the filling accuracy of other stations

A Low energy consumption (0. 37KW JSCC motor provides power, low energy

umption and long service life)

Expandable advantage(It can increase the number of filling heads on the original

basis then saving total costs)

The number of filling heads can be increased by production

capacity when needed

Four filling nozzle

Six filling nozzle

Automatic Engine Oil Filling Machine,The filling nozzle will not touch the bottle during filling process

The filling nozzle penetrates into the bottle mouth to prevent pollution

of the bottle body it prevents the bottle

damaged If the bottle

is soft and brittleness (such as broken bottles, withered bottles, etc

and once the bottle is broken, not only the bottle is lost

but also Contaminated machines, seriously affecting finished production capacity

Automatic Engine Oil Filling Machine-The finished product to show: