Automatic Essential Oil Filling Machine

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

Features of Automatic Essential Oil Filling Machine:

1. The contact parts of materials are made of 316 stainless steel, meeting GMP requirements.

2.Automatic Essential Oil Filling Machine adopts anti-drip Filling device.

3. Pneumatic components are controlled by PLC (German FESTO) and AirTac (Taiwan) with touch screen Settings.

4. The seals are made of silicone rubber (resistant to wear, high temperature, acid and alkali, corrosion) and fluororubber (resistant to wear, strong acid and alkali, corrosion).

5. The Automatic Essential Oil Filling Machine can remove the material outlet by removing the lengthened leather tube and arbitrarily move the Filling, so as to meet the requirements of unlimited (arbitrarily adjustable) Filling capacity over 1ml.

6. The liquid filling machine is not limited by the filling equipment and is a reliable and durable liquid filling machine.

Automatic Essential Oil Filling Machine

Automatic Essential Oil Filling Machine-Product description:

Automatic Essential Oil Filling Machine is a compact liquid filling and sealing machine, suitable for small batch filling of different products, widely used in medicine, herbal medicine, oral liquid, perfume, liquid, essential oil, olive oil, health care products, etc., pesticides, cosmetics, food and supplements.

Automatic Essential Oil Filling Machine-Product parameters:

| Product name | Automatic Essential Oil Filling Machine |

Max. Forming Depth | 12mm |

| Cutting speed | 0-25 times |

Packing Material | PVC/PET combined sheet (thickness:0.2-0.4mm) |

| 1-50ml | 1-50ml |

Power Supply | 220V/380V 50HZ (can be customized) |

Machine Weight | 850kg |

Machine Dimension | 2300*850*1450mm |

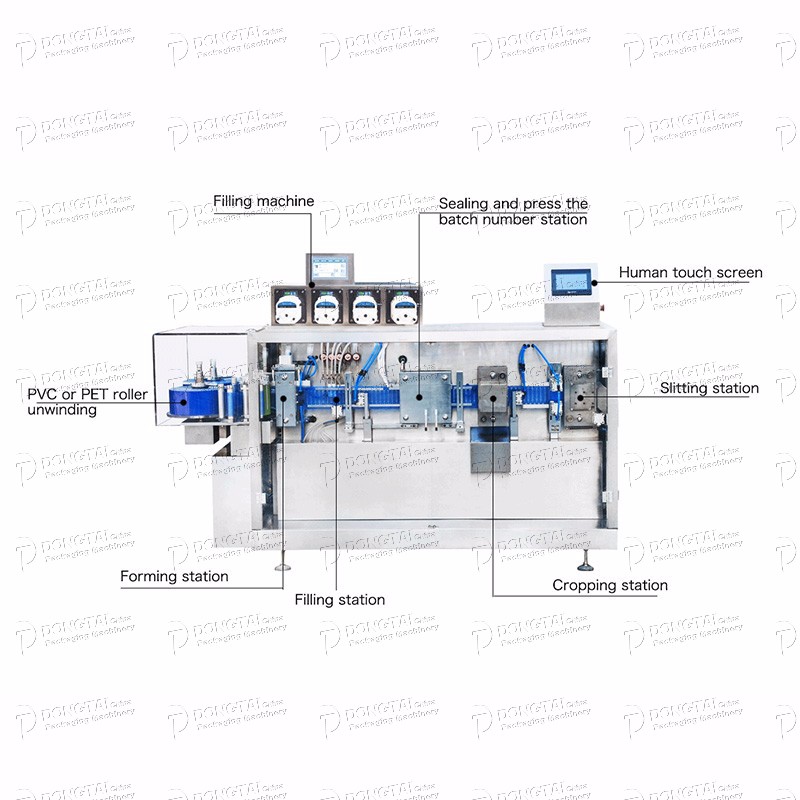

Automatic Essential Oil Filling Machine-Product details picture and description:

1.Automatic Essential Oil Filling Machine adopts PLC control and stepless frequency adjustment.

2.Automatic Essential Oil Filling Machine the following 6 workstations can be completed automatically through programming device, roller plate stripping, PVC/PE molding, filling, according to batch number, back end cutting and cutting

3.Automatic Essential Oil Filling Machine adopts man-machine interface for operation, which is simple and convenient

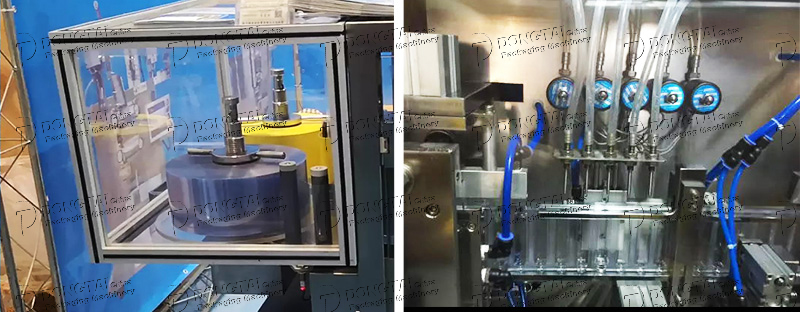

4. No leakage, foam and overflow of filling head.

5. The parts in contact with materials adopt SUS316L, which fully conforms to GMP standards.

6. The main pneumatic components and electrical components use well-known brand products.

7. Filling system adopts mechanical pump, accurate measurement, small difference.We can also design different pumps for different products, with various fluidity.

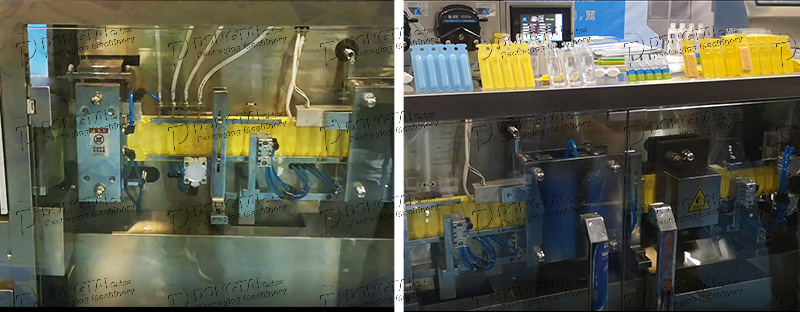

8.Automatic Essential Oil Filling Machine can be connected with labeling machine to realize the comprehensive production of filling, sealing and labeling.

Automatic Essential Oil Filling Machine-The finished product to show: