Automatic filling and sealing machine for olive oil glass bottles

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

This machine is widely used in all kinds of bottles, cans, and other special-shaped containers (100-1000 ml adjustable range of filling).

It can automatically complete a series of operations such as bottle feeding, counting, quantitative filling, and bottle discharging.

It is especially suitable for applications such as Automatic filling of walnut oil, sesame oil, tea oil, olive oil and other oils.

olive oil bottle filling machine---technical parameter

filling head | 4 | |||

productive capacity | 800-1000 b/h | |||

filling accuracy | ±1% | |||

filling range | 100-1000 ml | |||

locking head | single | |||

handing rate | ≥98%(It has a certain relationship with the quality of the cover) | |||

air pressure | 0.6-0.8Mpa | |||

voltage | 350v,50Hz | |||

power | 1.5kw | |||

Machine size | 1500*1160*1850mm | |||

olive oil filling and capping machine---Detailed Images:

1. The filling machine drives the piston through the cylinder, with automatic quantitative, anti-drip filling head and vacuum suction device to ensure that the production workshop and packaging products are not contaminated, and the machine has a bottle mouth positioning and positioning system and a liquid level control system .

2. This machine can be used for liquid filling of various oils, disinfectants, eye wash liquids, nutrition liquids, pesticides, medicines, perfumes and other industries.

3. The liquid automatic filling machine is made of 304 stainless steel, which fully complies with GMP standards;

4. The filling speed and filling volume are convenient and adjustable. Bottles of different specifications and shapes can be replaced without the need to replace parts. It is easy to adjust.

5. Bottleless, non-filling, automatic start and stop, accurate filling quantity and counting function, simple and convenient in use operation, installation adjustment, equipment cleaning (with one-button cleaning function), maintenance and so on; the equipment is easy to adjust 、 Filling volume is accurate and has counting function

| 1.Stainless steel integrated, stainless steel suction cylinder | 2.Vacuum suction |

|  |

| 3.The whole machine is made of stainless steel, and the frame is made of stainless steel or industrial aluminum. | 4.Customized (specially for grease materials) to increase production capacity while ensuring filling accuracy. |

|  |

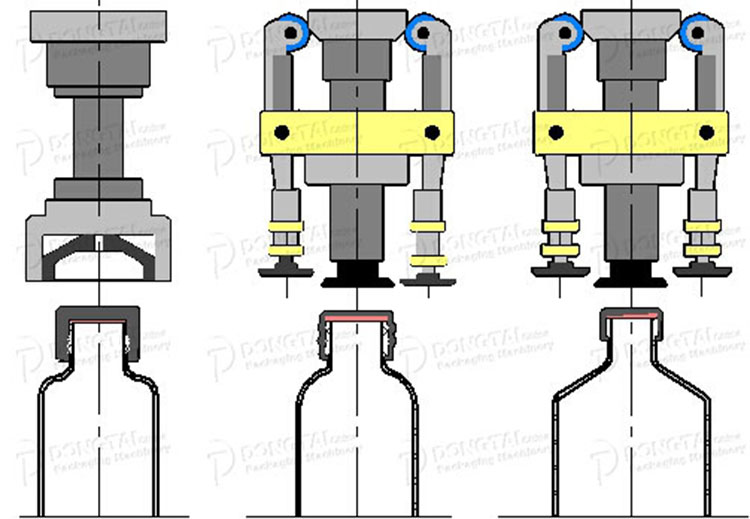

automatic locking machine

product introduce:

features:

1. The machine is equipped with an automatic detection device, that is, the cap is automatically stopped when the cap is full, and the cap is automatically opened when the cap is missing; 2. The machine is equipped with a coverless automatic alarm device. That is: when the bottle cap in the capping machine is about to run out, the machine automatically buzzes an alarm to remind the operator to add the bottle cap as soon as possible to ensure normal production.

1.Vibration plate

2.locking type

Turkish customer site:

Turkish customer site: