200kg dispenser oil automatic filling machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

200kg dispenser oil

Instructions for use

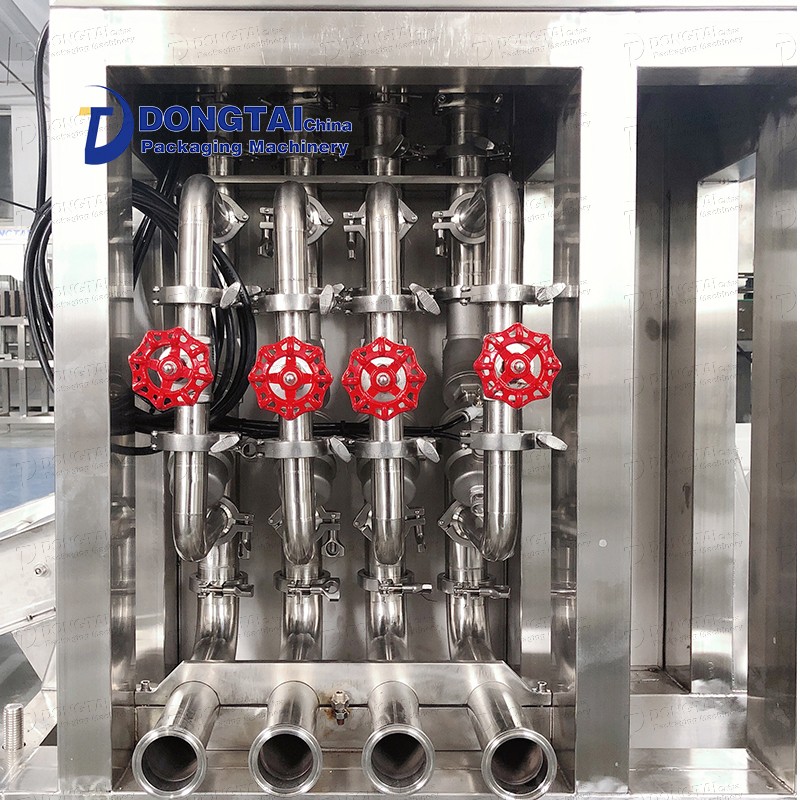

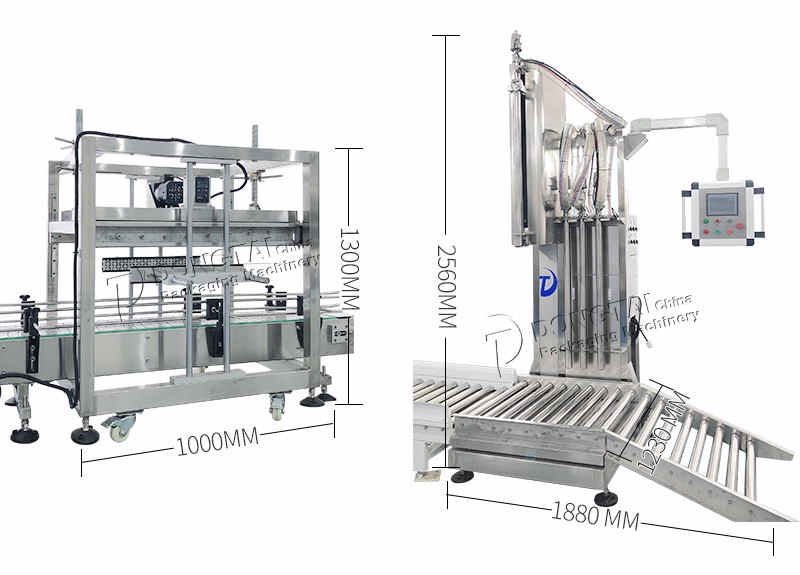

The 200 kg oil filling machine is an automatic weighing and packaging equipment for liquid materials in the chemical, grain and other industries. It adopts high-precision full electronic weighing and metering to control the automatic quantitative filling operation of the raw material barrel. It has a high degree of automation, can avoid material overflow to the greatest extent, and prevent the material itself from polluting the environment, thereby effectively protecting the safety of the operator, and the system can be used in humid, dangerous or other harsh environments. Liquid quantitative filling machine is suitable for syrup, paint, essential oil, perfume dispenser, adhesive, curing agent, resin, dye, cleaning agent, machine oil, glycerin, lubricating oil, edible oil, fragrance, solvent, additive, food additive, pesticide, etc. Quantitative filling of hazardous chemical products.

Product Description

200kg dispenser oil automatic filling machine

Product name | 200 kg oil filling machine |

Operation | One-click operation |

Function | Filling grease |

Suitable for | Motor oil |

Feature | Effortless design |

capacity | 5-200kg/barrel |

Filling capacity | 100-150 barrels/hour |

Capping machine

Capping machine products are mainly used for opening barrels, paint barrels, lubricating oil barrels, packaging barrels, paint barrels, portable barrels (convenient barrels) series: 4 liters, 5 liters, 10 liters, 12 liters, 18 liters, 20 liters, necessary Special tools for standard lids. It is widely used in barrels, cans, lubricants, paints, chemicals, petroleum, grains and oils, and other important products in the liquid packaging industry. The capping machine is an important part of the production line, which is used to complete the capping of heavy barrels. The capping machine is two capping machines to ensure the tightness of the capping and the flatness after capping. The capping machine is directly transported under the capping machine by a power conveyor belt, and the continuous capping is carried out by an inclined roller conveying device, and the capping is tight and reliable.

FAQ

1. What is your delivery time?

Answer: It usually takes around 30 days to manufacture the whole production line. For emergent needs of special parts, the process could be shortened.

2. What is the warranty and how is the after-sale service?

Answer: We provide one-year warranty which does not include easily damaged spare parts, such as heaters, belts, etc. Technicians will guide you to install, test machines, and provide free training to your staff in terms of operating and maintaining the machines. Operating manuals will also be sent with machine or by email.

3. Can you arrange technicians for overseas debugging?

Answer: Yes, we can provide services as needed exclude visa fees, round-trip air tickets, and accommodation. We can also arrange your technicians to study in our factory before shipment.

4. Is the machine available with 415V/380V /220V/110V?

Answer: We provide solutions and converter to different power sources and different plug bases for customers from all over the world.

5. Are you a manufacturer or trade company?

Answer: We are a manufacturer in filling and packaging machine field more than a decade. With experienced engineer and technician team, we can provide the best solution to your requirement. If you are interested, we can arrange factory tour for you.

6. Do you have any certification?

Answer: We are CE and ISO9001 certified company.