Automatic freezing vat lubricating oil filling machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

Vat lubricating oil filling machine is a kind of equipment used for automatic weighing and packaging of liquid materials in the chemical, grain, and other industries. It adopts high-precision fully electronic weighing and weighing measurement to control the automatic quantitative filling and filling operation of the raw material barrel. Its high degree of automation can avoid material overflow and prevent the material itself from polluting the environment, thereby effectively laboring for the operator At the same time, the system can be used in humid, dangerous or other bad environment.

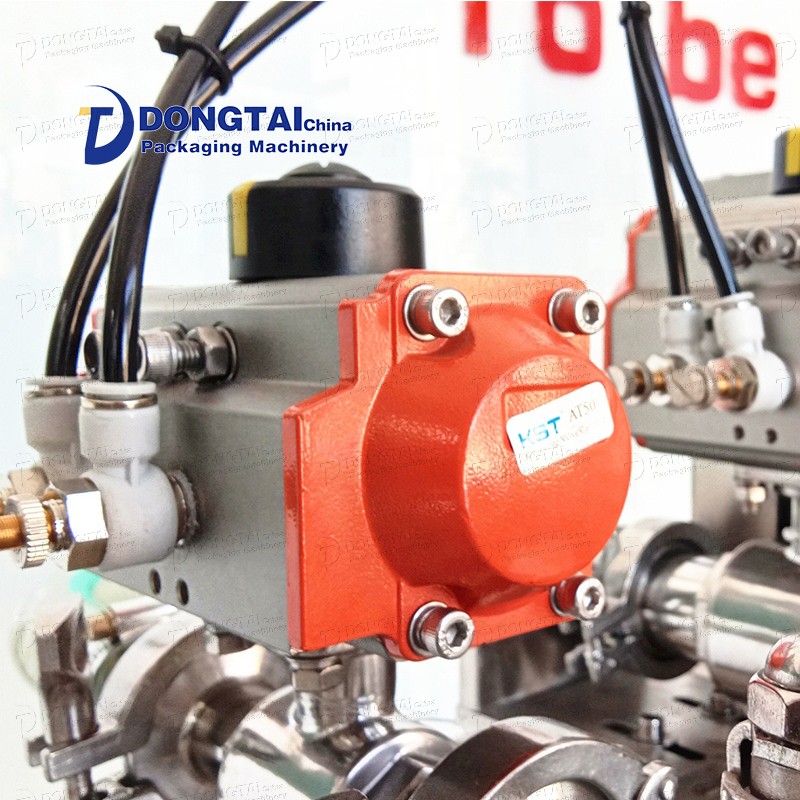

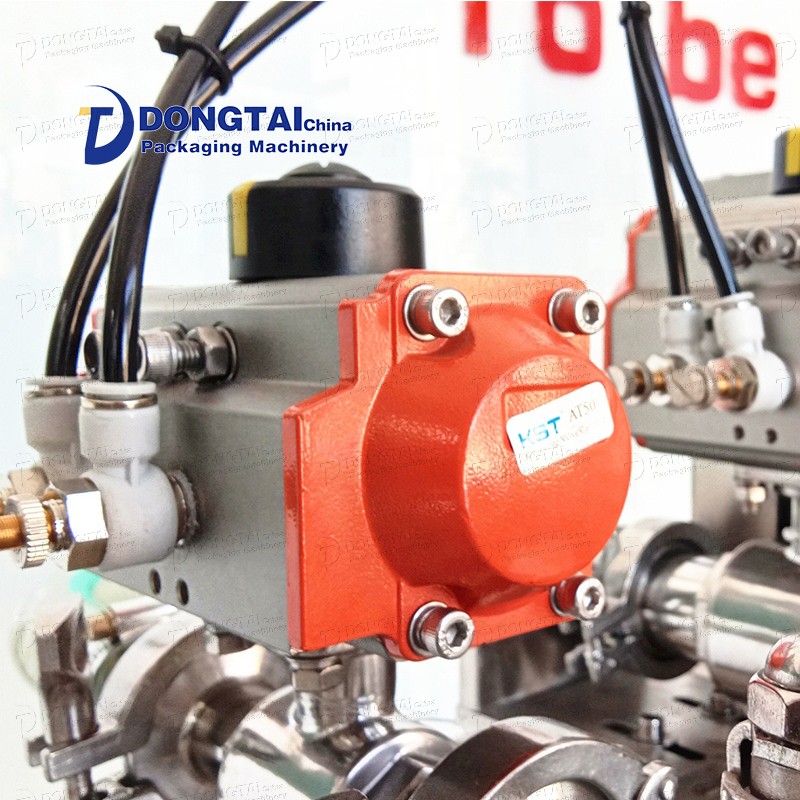

Material structure of oil filling machine:

All parts in contact with materials are made of high-quality stainless steel, and the main electrical components are imported with original packaging. The whole machine is beautiful and elegant and meets the requirements of GMP standards. The disassembly and cleaning of the liquid cylinder and its pipeline are convenient and quick.

Scope of application:

Vat lubricating oil filling machine is suitable for the quantitative filling of olive oil, mustard oil, bottled motor oil, hair growth oil, palm oil, vegetable oil, food additives, pesticides and other dangerous chemical products.

Operating procedures:

Operating procedures:

A. The operator places the empty barrel on the weighing platform so that the filling gun head is directly above the barrel mouth;

B. The operator presses the [Start] button;

C. Automatically inspect the container weight to be qualified, automatically remove the tare weight, dive the filling head, and open the valve and the bottom valve of the gun head for rapid filling. When the weight reaches the small material value, the filling speed becomes smaller, and the weight reaches the target amount and reduces the lead When the second valve is fully closed, the error is detected and displayed;

D. The operator moves the heavy barrel out of the weighing table, and a filling process is completed;

E. Repeat steps A-D for continuous filling.

F. Manually push out the heavy barrel and lock the lid. The filling process is complete.