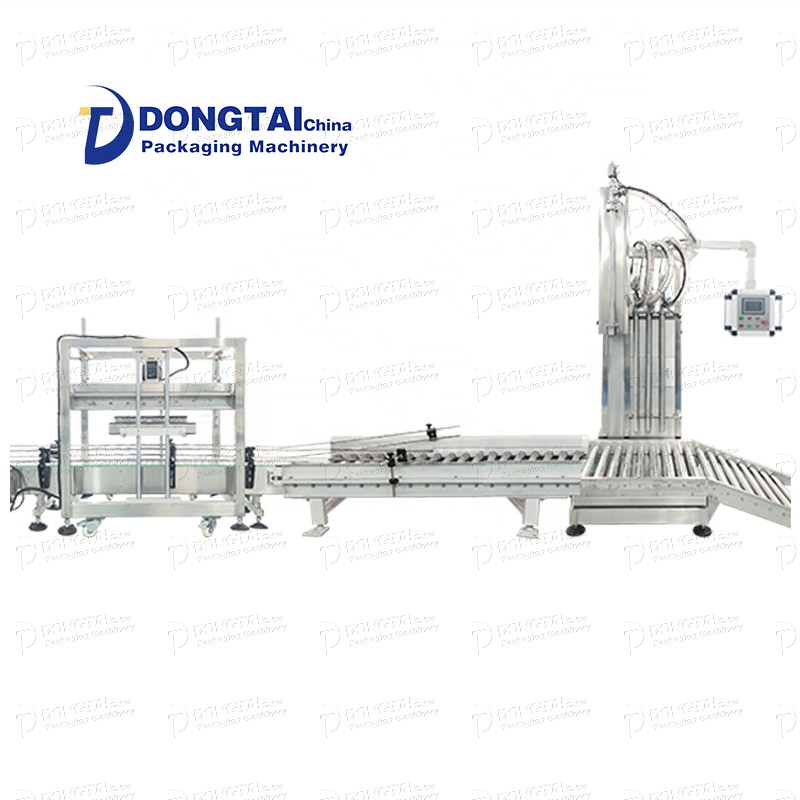

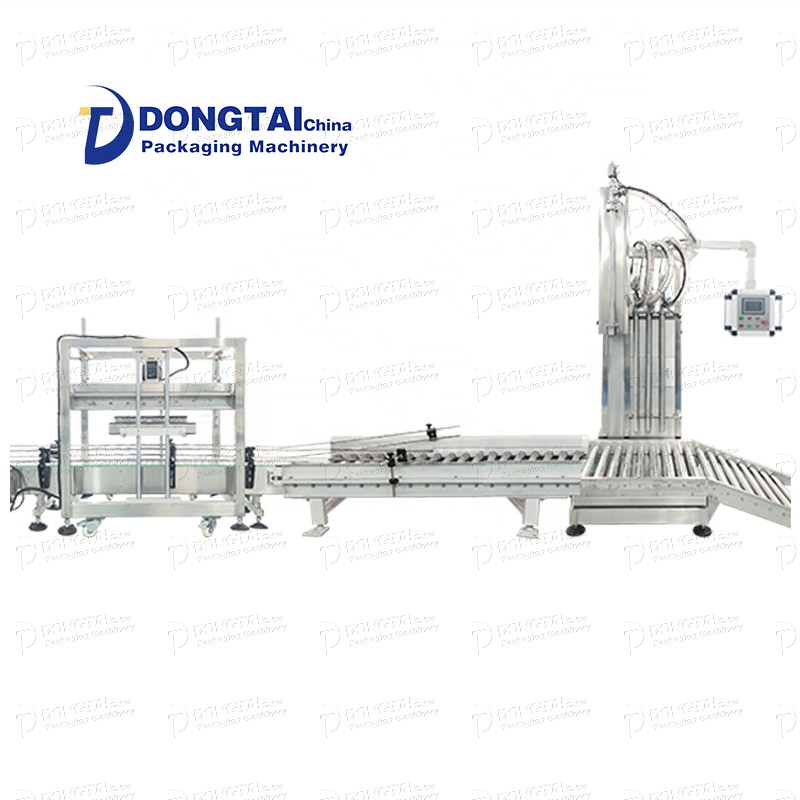

Automatic lubrication filling machine line edible oil filling and packaging machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

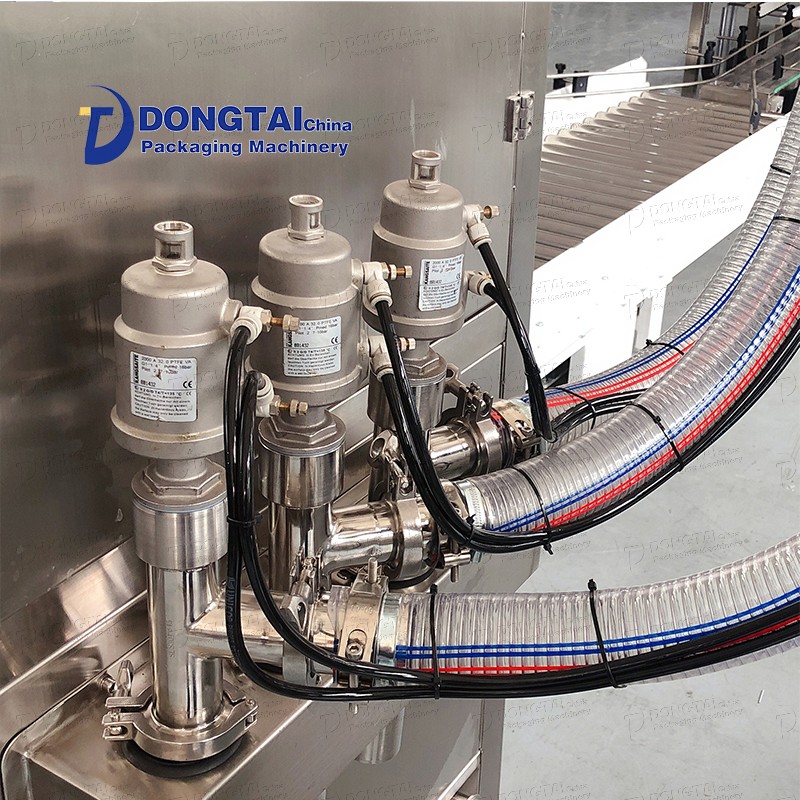

The oil and lubricating oil filling machine uses 316L stainless steel plunger metering pump for filling. Different pump specifications and different filling heads can be selected according to the actual production volume of the user, and it can be easily linked with the bottle machine and capping machine. produce. The oil filling machine production line has been widely used in the oil packaging of automobiles, motorcycles, engines and other industries, and fully meets the requirements of GMP (Good Operating Practice) specifications.

Product introduction:

The production line of the automatic oil automatic filling line adopts the filling method of flowmeter, one-to-one system design, one-to-one system design, each system can be used independently without being affected, and the equipment can complete automatic quantitative filling of different bottle types; The filling head has its own suction function to prevent oil spills. The top of the filling machine is equipped with a storage box, and the inside of the storage box is designed without storage. The storage box must have high and low liquid level devices, high and low liquid levels The signal requirement is 24V, 4~20mA, output by the terminal block.

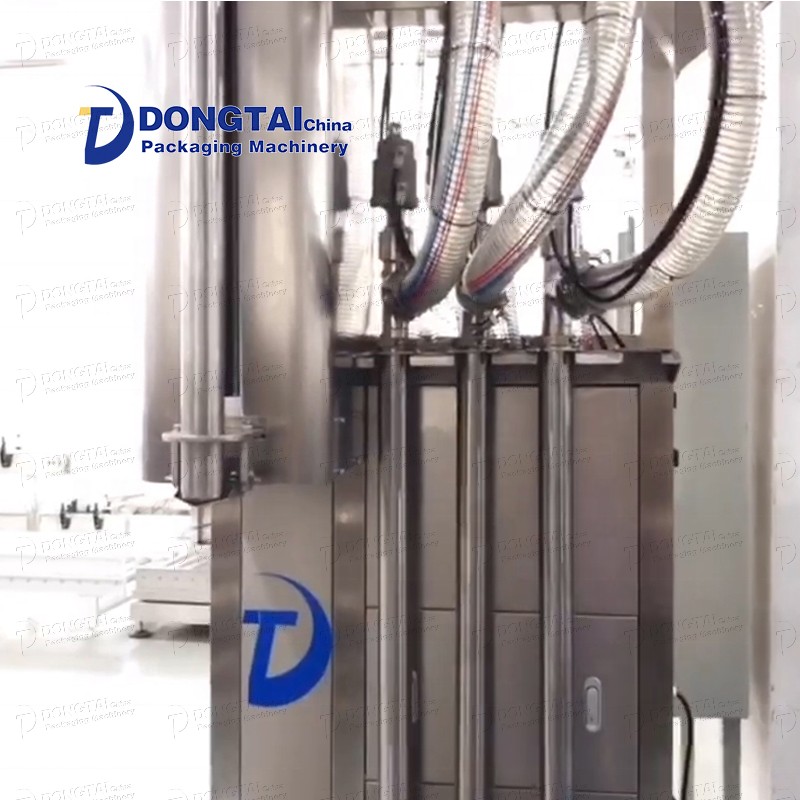

Color touch screen:

Automatic lubricating oil filling imported programmable PLC and color touch screen, the lubricating oil filling machine filling control system is more accurate and reliable

Formula parameters

It can store more than 20 groups of formula parameters. When filling materials of different specifications and densities, the parameters of the oil injection machine can be stored in a predictable manner.

Anti-drip filling head

Refined from 316L stainless steel, specially designed for sauce filling, through the model, the internal and external refueling machine is finely polished, the engine refueling line is truly food-grade