automatic paste filling machine tooth paste machine filling paste filling sealing machine cosmetic filler machine filling machine paste

- DONG TAI

- CHINA

- 15 WORKING DAYS

- 1000 SETS/YEAR

1. The automatic paste filling machine is highly automated and reduces labor.

2. The tooth paste machine filling is equipped with a central positioning device controlled by an electric eye, and the rotating hose mold is automatically positioned.

automatic paste filling machine tooth paste machine filling paste filling sealing machine cosmetic filler machine filling machine paste

PRODUCT INTRUDUCTION

The paste filling sealing machine is a machine that automatically completes the entire process of supply, cleaning, labeling, filling, hot-melting, sealing, coding, trimming and finished products. The automatic paste filling machine is commonly used in the filling and sealing of plastic tubes and aluminum-plastic composite tubes in medicine, food, cosmetics, and daily chemical products. The automatic paste filling machine has a very wide range of applications.

PRODUCT FEATURES

The tooth paste machine filling has a simple design, a compact structure and a small footprint.

The cosmetic filler machine filling machine paste completes the supply and cleaning of the tube by pneumatic. The action is accurate and reliable.

The paste filling sealing machine is easy to adjust, especially suitable for large diameter hoses.

The automatic paste filling machine is made of 316L stainless steel that meets GMP requirements, which is safe and easy to maintain.

The cosmetic filler machine filling machine paste has an intelligent temperature control system

MAIN PARAMETER

Product Name | Automatic mashed potatoTube Filling Machine paste filling machine |

Material | stainless steel |

Type | Paste Filling Machine |

Filling range | 5-50ml(Customizable as required.) |

Machine Dimension | 1900(L)*850(W)*1910(H)mm |

Power | 220v/380v |

Rate Of Work | 1.5kw |

Pressure | 0.4-0.6MPa |

paste filling machine---Suitable for material display:

1. Technical support online service provided.

2. Technical files service provided.

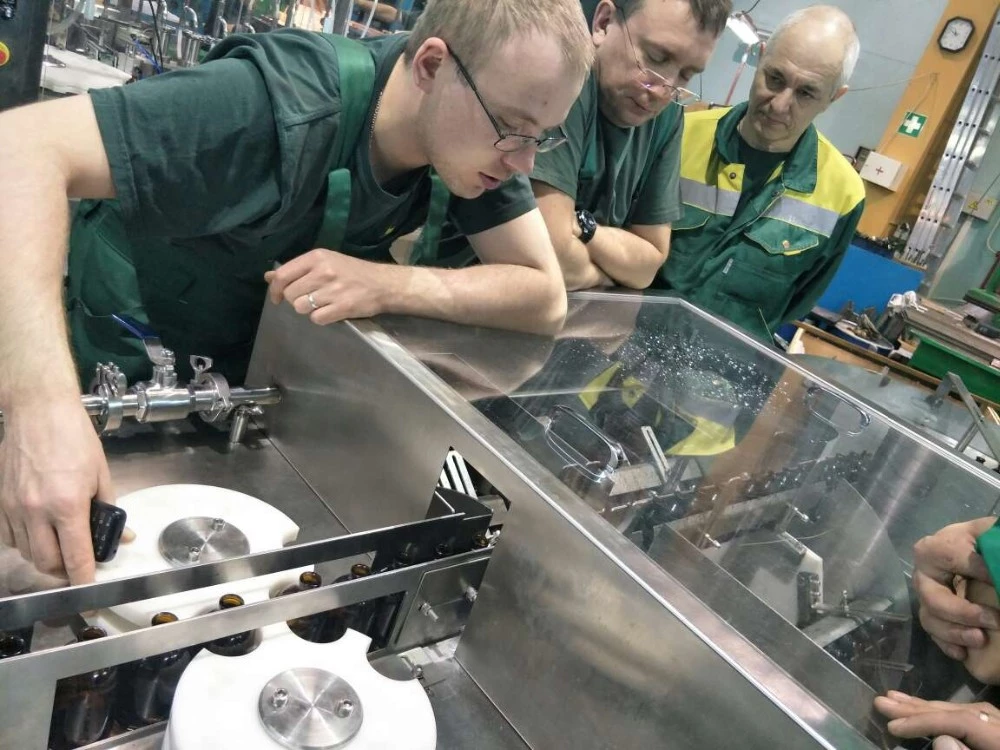

3. On-site training service provided.

4. Spare parts replacement and repair service provided.

FAQ: