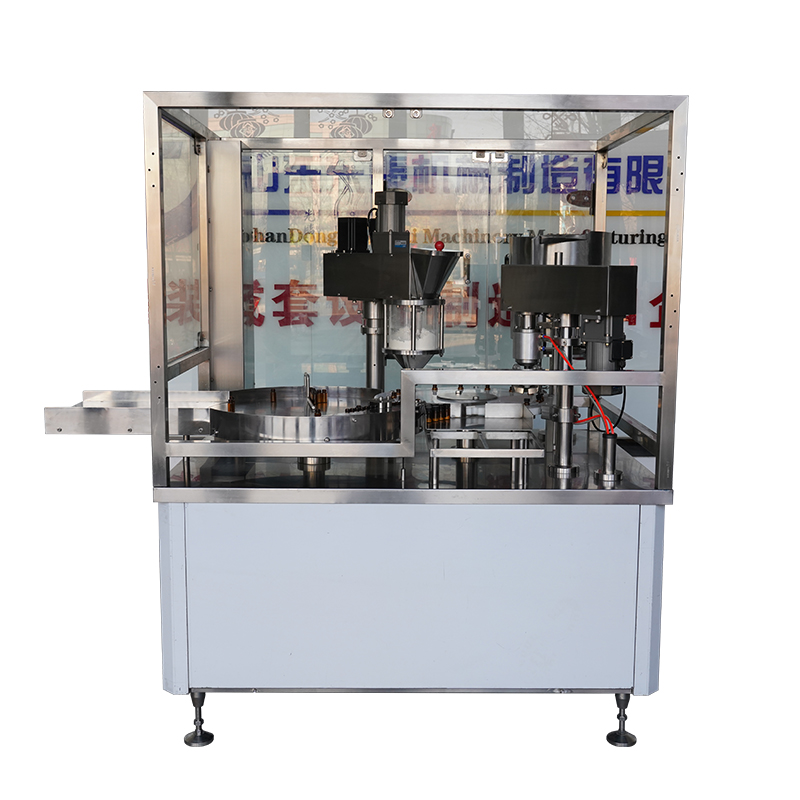

Automatic powder bottle filling machine

- DONG TAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

Easy to operate, real-time ink volume detection, ink/solvent changes (prove no mess or error);

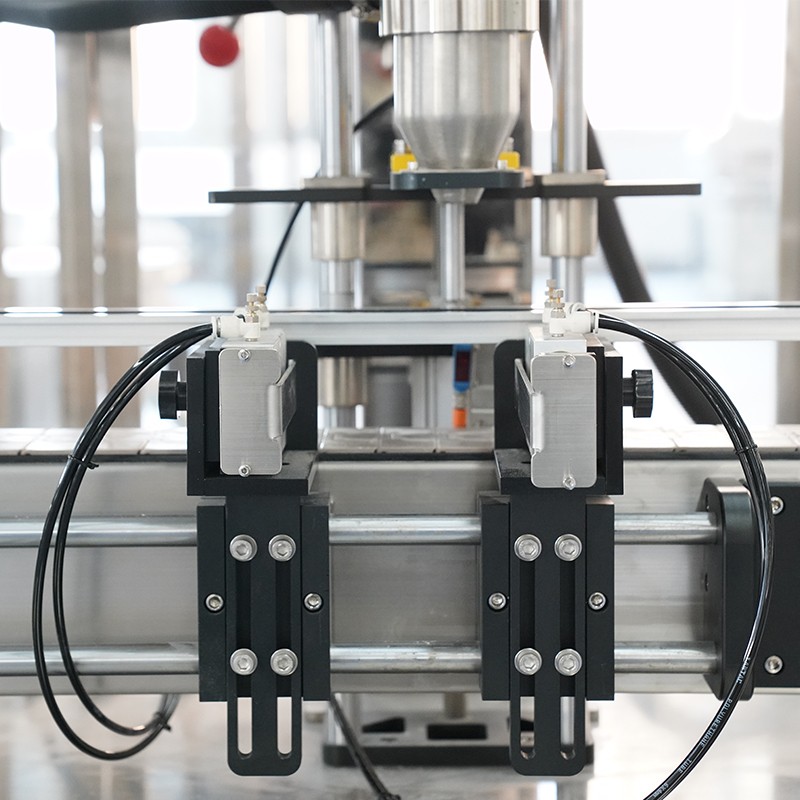

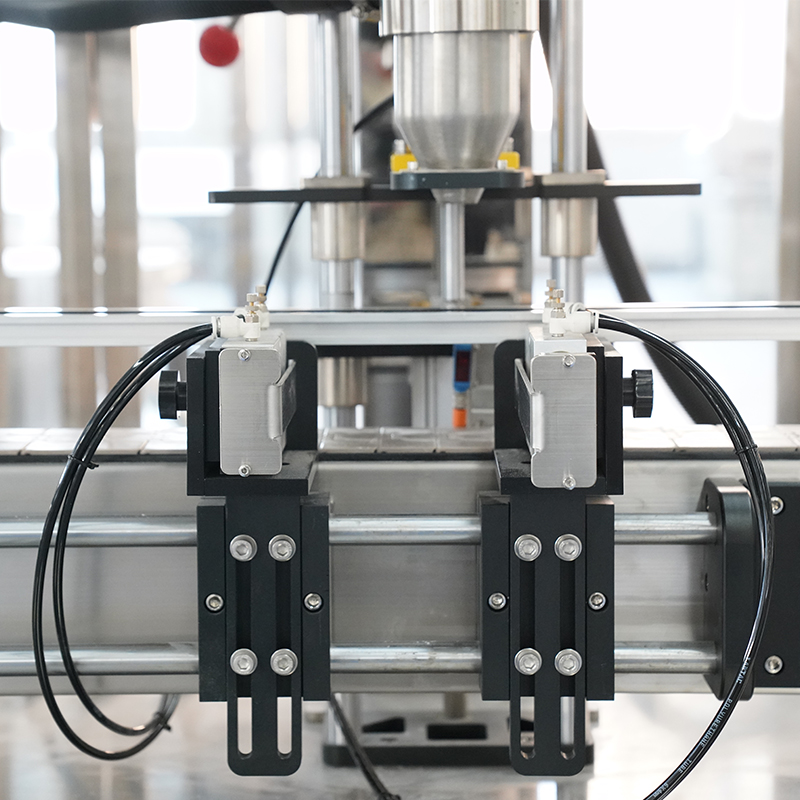

This machine is the main machine for powder distribution in the powder filling machine. It is used for powder metering, filling, capping, capping, capping and sealing of vials. The bottles of the powder filling machine enter the plate one by one from the bottle feeding machine. The filling plate moves intermittently to transport the bottles through the filling station, capping station, capping station and bottle discharge station. When the bottle arrives at the filling station, the photoelectric switch sends a signal to the system, and then the filling head fills the bottle once. When the bottle reaches the bottle cap station, the bottle cap will be automatically put on the bottle mouth. The capped bottle arrives at the capping station.

powder filling machine In order to obtain the best uptime and reliability, the Willett small character inkjet printer can manually clean the PH every five days, while competitors need to clean it once a day;

powder filling machine Easy to operate, real-time ink volume detection, ink/solvent replacement (will not cause confusion or errors);

powder filling machine Easy to maintain, no need to replace the filter. Due to the sleeve design, there are fewer steps to clean the spray base and no adjustments are required.

The powder filling machine installation and commissioning service is carried out by a full-time service engineer with many years of relevant experience in charge of the equipment installation and commissioning to the qualified acceptance, and the equipment enters the production state. And cooperate with the production company to conduct employee training, so that the company has a team of skilled equipment use and maintenance personnel.

The powder filling machine is mainly used for quantitative packaging of protein powder, pesticides, veterinary drugs, premixes, bulk powders, additives, milk powder, starch, medicines, enzyme preparations, feeds, etc., to ensure a filling accuracy of 1‰. The filling speed is increased by 20%-35%. The operation is simple, the labor cost is saved, and the production efficiency is high.