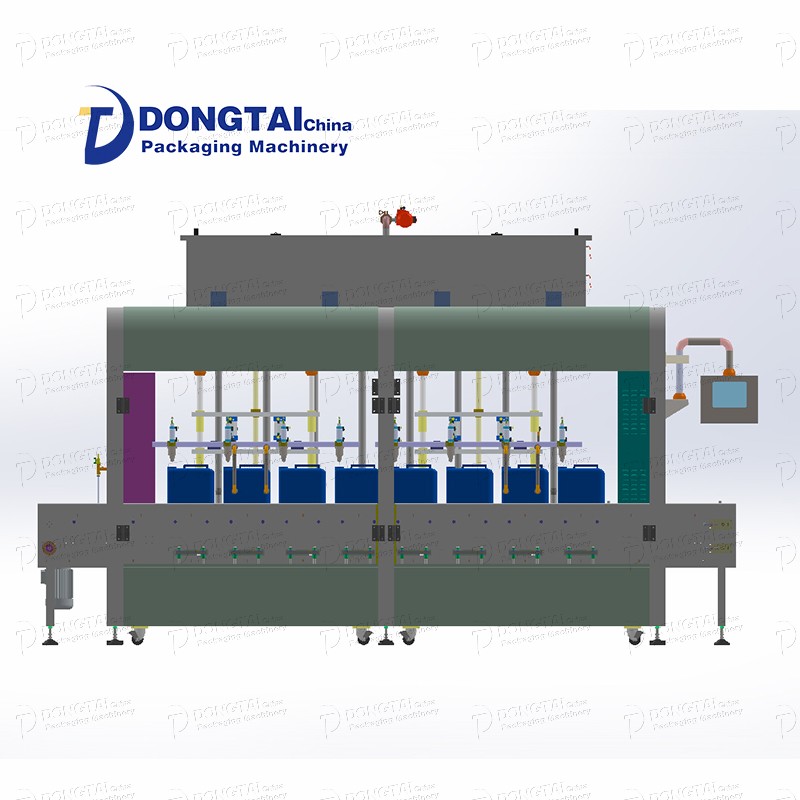

Weighing oil filling machine bottle oil bottle filling machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

This series of filling machines are suitable for liquid products such as edible oil and lubricating oil.

The whole machine adopts PLC microcomputer control, which can adjust the whole automatic cooking oil filling machine or fine-tune the single head. The filling is accurate, the operation is convenient, and the labor is saved; the photoelectric sensor, Proximity switches, etc. are all advanced sensor elements, so that no bottle is not filled, the host will automatically stop and alarm when the bottle is blocked.

weight filling machine---technical parameter:

Filling head | 8 heads |

Filling range | 10L,20L |

Filling speed | 1000-1200b/h(10L).500-800b/h(20L) |

Filling accuracy | ±0.1% |

Voltage | 380V 50/60Hz |

Power | 2.5kw |

Air pressure | 0.5-0.7MPa |

The diameter of bottle mouth | ≥φ40mm |

Machine size | 4500×1660×3000 |

bottle oil bottle filling machine automatic---Details show:

bottle oil bottle filling machine automatic---Details show:

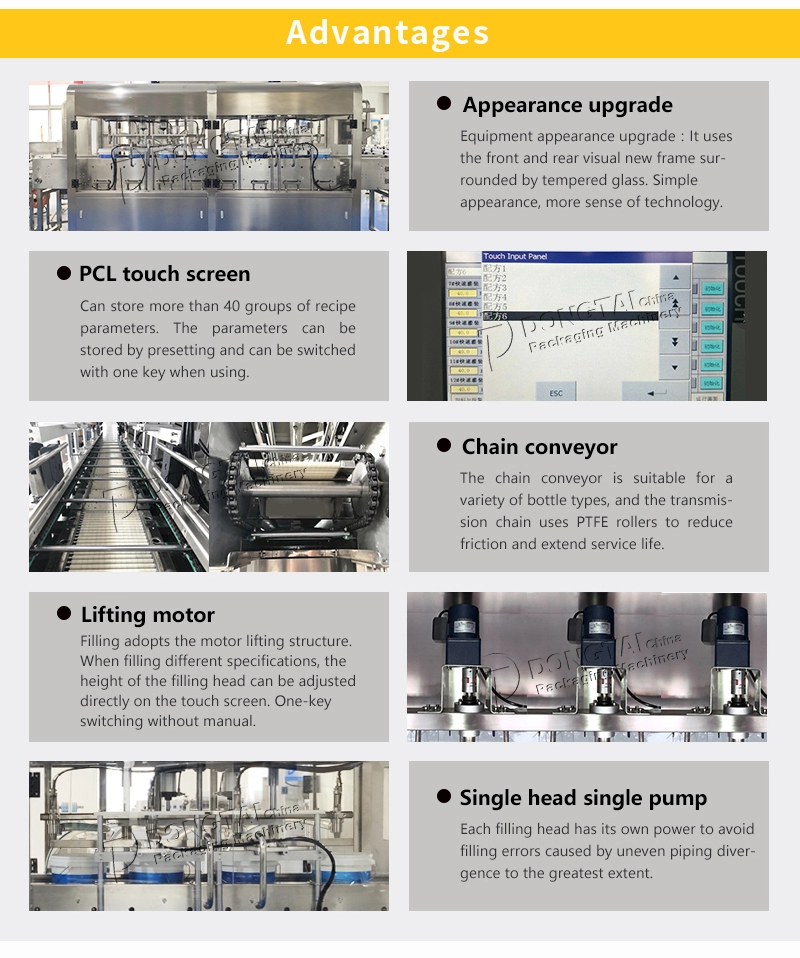

1. The equipment comes with a buffer tank to avoid large filling errors caused by uneven pipeline pressure; patented intelligent control system, 8-head cooking oil filling machine uses 9 sets of inverter control, one-key switching, automatic feedback, automatic proofreading; included High-level tank, high-frequency multi-stage filling speed can be adjusted at will, filling machine oil operation program optimized, can store more than 40 sets of formula parameters, when filling materials of different specifications and different densities, the parameters can be preset and stored, and one-key switching during use , The operation is more simple and convenient, and at the same time, the technical ability requirements of the operators are reduced.

2. The filling adopts a motor lifting structure. When filling different specifications, the height of the filling head can be directly adjusted on the touch screen, one-key switching, no need for manual repeated positioning and adjustment, which is more convenient.

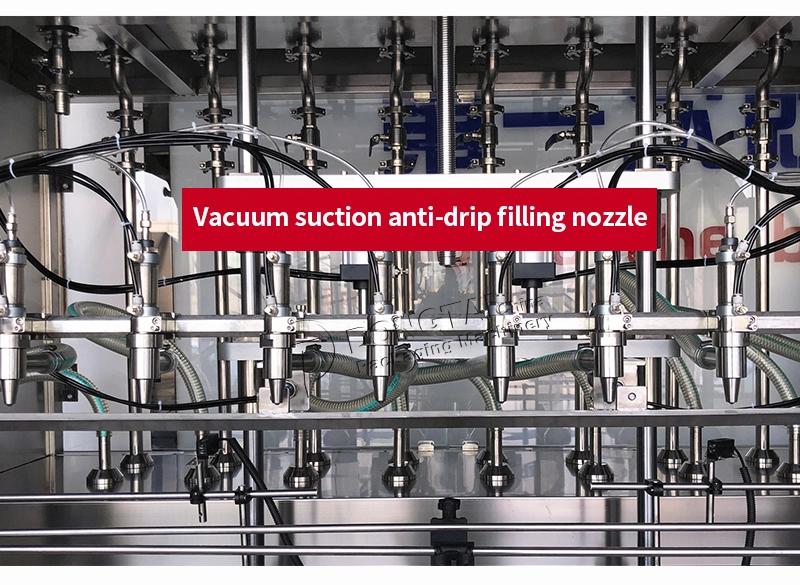

3. Anti-drip filling head

Adopting the utility model patent certified by the State Intellectual Property Office: vacuum suction and anti-drip filling head; patent certificate number: ZL2013 2 0358214.7; patent certification time: June 2013. Patented design and vacuum suction system are specially designed for edible oil filling to ensure that there is no leakage during the filling process, and will not pollute the conveyor chain and bottle body. The filling head and cylinder adopt a split mechanism, which can be disassembled separately and will not appear. Liquid leakage damages the cylinder. Standard parts are used for seals and other accessories, which is easy to replace and maintain. After the filling is completed, the air cylinder in the filling head is designed with a self-sealing structure. At the end of a production shift, even when the power is cut off, the air supply is still not leaking.

4. The appearance of the equipment is upgraded: adopting a new front and rear visible frame, front and rear toughened glass, the appearance is simple and more technological;

5. Chain conveying is suitable for filling a variety of bottle types. The conveying chain adopts PTFE rollers, which makes the bottle move more stable, reduces friction, is more wear-resistant, durable, and extends the service life of the equipment. The O-shaped baffle is used to shield the disadvantages of the tensioner (using fish eyes to adjust the tightness of the sprocket), the conveying adopts PTFE roller type, the container conveying is more stable, the bottle mouth positioning is more accurate, and the forward and reverse conveying can be realized.