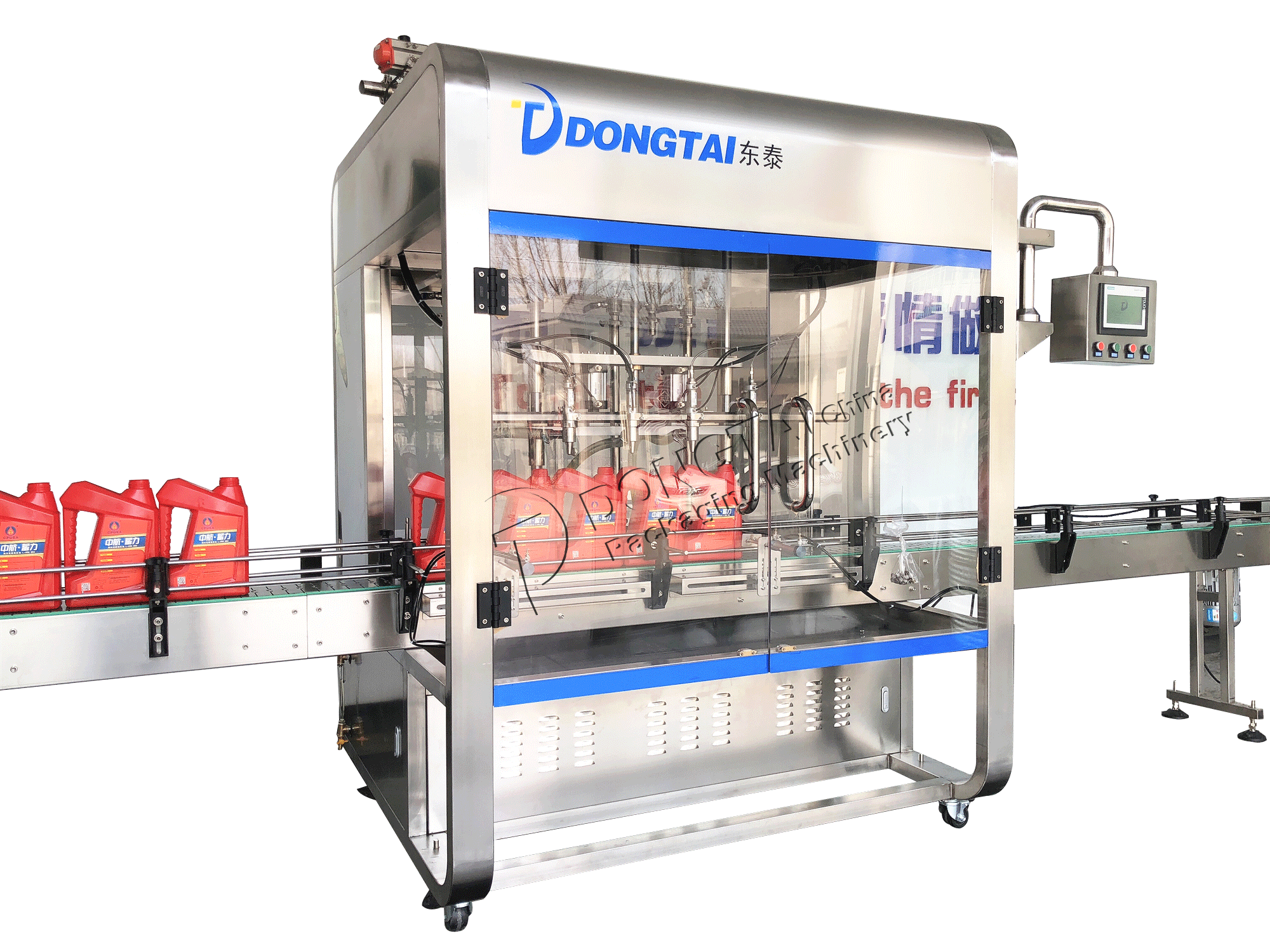

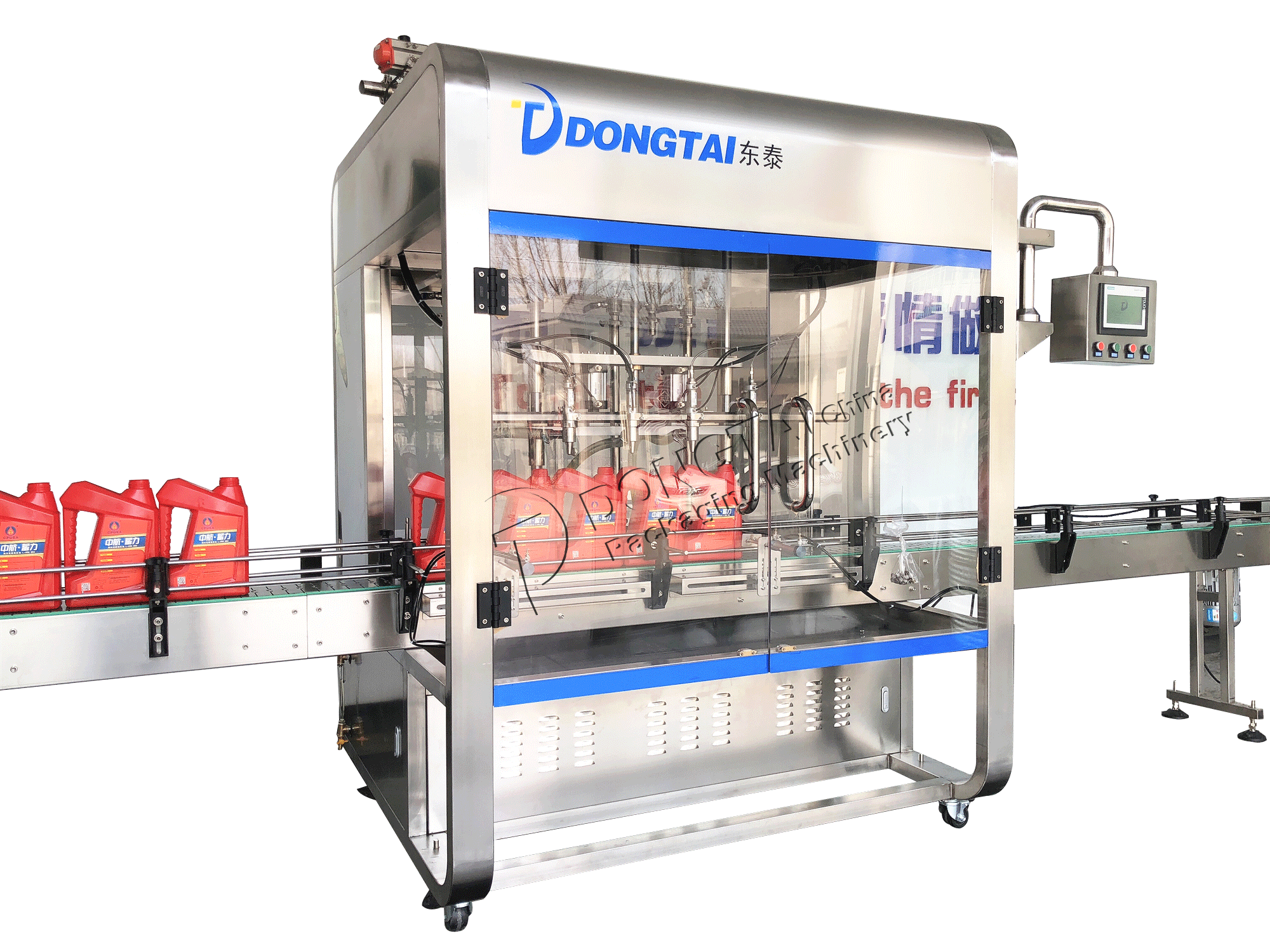

Filling machine liquid soap filling bottle filling machine sachet liquid shampoo

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

Warranty:

1 YEAR for machinery warranty|1 YEAR for Core Components

Shipping:

Support Sea freight

Customization:

Customized logo (Min. Order: 1 Sets)

Customized packaging (Min. Order: 1 Sets)

Graphic customization (Min. Order: 1 Sets) Less

Product Description

Automatic liquid alcohol disinfection filling machine

user's guidance

The filling machine adopts the utility model

Certified by the State Intellectual Property Office, single head, single pump, single frequency filling control system, patent certificate number: ZL 20132 0356808.4, patent certification time is November 2013.

Each filling head of the filling machine is an independent control system, and customers can flexibly set the number of filling heads to be used according to their own output. Each filling head does not affect each other, and when one of the filling heads needs maintenance, it will not affect the filling operation of the entire machine.

illing volume | 1-5L |

Filling capacity | 1200-1700BPH |

Voltage | 220v/380v 50/60 HZ |

Machine size | 1800*1200*1770mm |

Food grade filling head

The connecting pipe is made of 304 stainless steel double-layer braided pipe, which has strong pressure resistance and good flexibility.

Vacuum suction

The vacuum suction function can ensure that it will not drip during the filling process and will not contaminate the conveyor chain and the bottle. The black tube is the air tube, and the white tube is the vacuum straw.

The filling head and the gas cylinder adopt a separate mechanism, which can be disassembled separately without liquid leakage or damage to the gas cylinder. Imported AirTac cylinders are durable, and other parts are standard parts, which are easy to replace and maintain.

PLC control system

PLC and color touch screen make the filling control system more accurate and reliable.

Optimized filling machine operation program, can store more than 20 formula parameters. When customers fill materials with different specifications and densities, parameters can be stored by default. When in use, the parameters can be switched by one key, which makes the operation easier and faster. Convenience, reducing the requirements for the operator's technical ability.

FAQ

1. What is your delivery time?

Answer: It usually takes around 30 days to manufacture the whole production line. For emergent needs of special parts, the process could be shortened.

2. What is the warranty and how is the after-sale service?

Answer: We provide one-year warranty which does not include easily damaged spare parts, such as heaters, belts, etc. Technicians will guide you to install, test machines, and provide free training to your staff in terms of operating and maintaining the machines. Operating manuals will also be sent with machine or by email.

3. Can you arrange technicians for overseas debugging?

Answer: Yes, we can provide services as needed exclude visa fees, round-trip air tickets, and accommodation. We can also arrange your technicians to study in our factory before shipment.

4. Is the machine available with 415V/380V /220V/110V?

Answer: We provide solutions and converter to different power sources and different plug bases for customers from all over the world.

5. Are you a manufacturer or trade company?

Answer: We are a manufacturer in filling and packaging machine field more than a decade. With experienced engineer and technician team, we can provide the best solution to your requirement. If you are interested, we can arrange factory tour for you.

6. Do you have any certification?

Answer: We are CE and ISO9001 certified company.