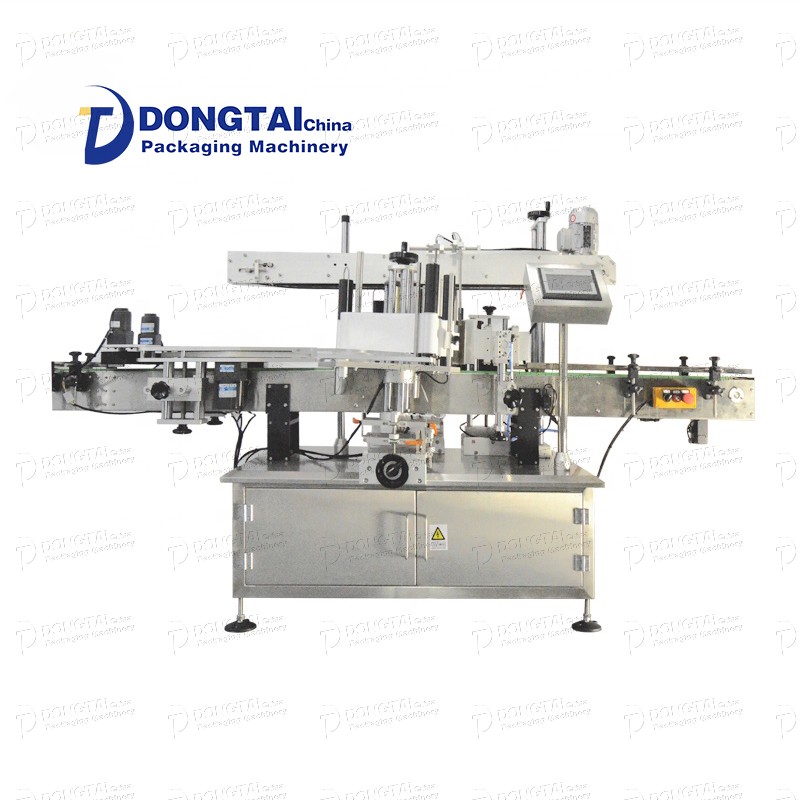

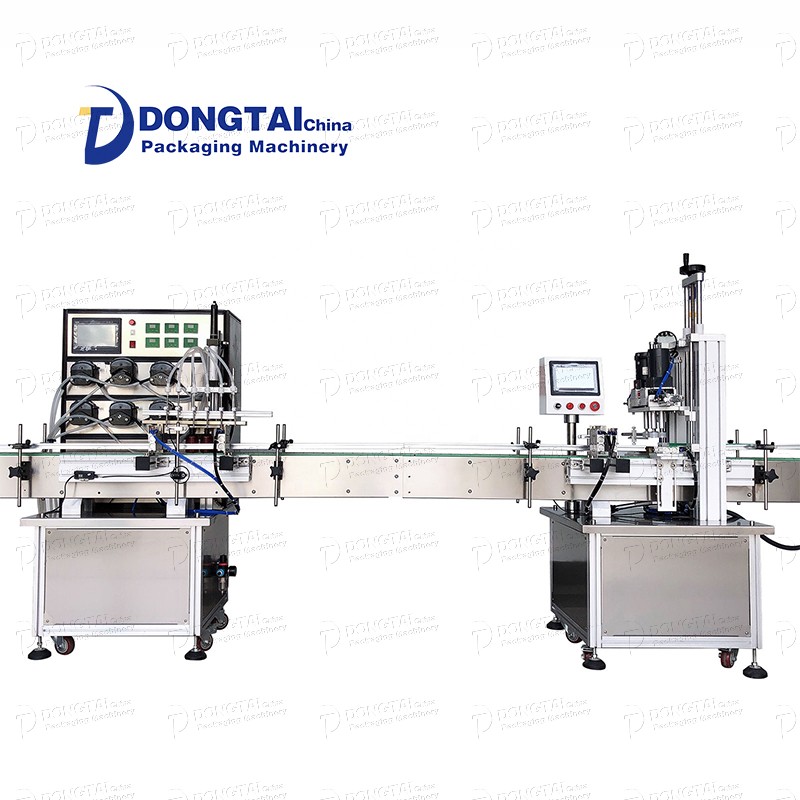

Automatic 1-4L lubricating oil filling machine High precision automatic oil filling production line

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

The lubricating oil filling machine adopts the filling method of the flow meter and the one-to-one system design. Each system can be used independently without being affected. The equipment can complete the automatic quantitative of different bottle types; the filling head has its own suction function to prevent Oil spills, there is a storage box on the top of the filling machine. The storage box is designed to be free of storage. The storage box must have high and low level devices. The high and low level signal requirements are 24V, 4-20mA, Output by the terminal block.

Machine application range: The machine adopts flow meter measurement, touch screen control, one-key adjustment of parameters, convenient and fast. It can be filled with various greases and oils. The filling head adopts a special grease anti-drip filling head, which does not drip. The machine is set with fast and slow speed technology, which can be fast and then slow to prevent material splashing. Keep the production workshop clean and clean.

Machine application range: The machine adopts flow meter measurement, touch screen control, one-key adjustment of parameters, convenient and fast. It can be filled with various greases and oils. The filling head adopts a special grease anti-drip filling head, which does not drip. The machine is set with fast and slow speed technology, which can be fast and then slow to prevent material splashing. Keep the production workshop clean and clean.

Product advantages:

1. The system can store 20 groups of formulas. After the storage is completed, they can be called at any time during the production process in the future, switching within one second, the operation is simple and very convenient;

2. The air washing function is added to the lubricating oil filling machine, which makes it very convenient to clean the equipment when filling different oils;

2. The air washing function is added to the lubricating oil filling machine, which makes it very convenient to clean the equipment when filling different oils;

3. This filling method and material contact parts are made of sanitary stainless steel 304, no pollution during the filling process, easy to change and clean each material, easy to maintain and clean at the end of the workshop, which is much better than other filling methods. Especially for the filling of heavy-duty gear oils with large numbers and high viscosity, it is a common filling method in the lubricating oil industry.

4. We use sub-system power control and material supply to increase the filling speed; while increasing the filling range, the filling method has been improved, and the filling accuracy has been greatly improved, with an error within 1‰.

4. We use sub-system power control and material supply to increase the filling speed; while increasing the filling range, the filling method has been improved, and the filling accuracy has been greatly improved, with an error within 1‰.