High - Quality Automatic Edible Cooking Vegetable Soybean Peanut Bottle Oil Liquid Filling And Capping And Labeling Machine

- dongtai

- china

- 7days

- 100

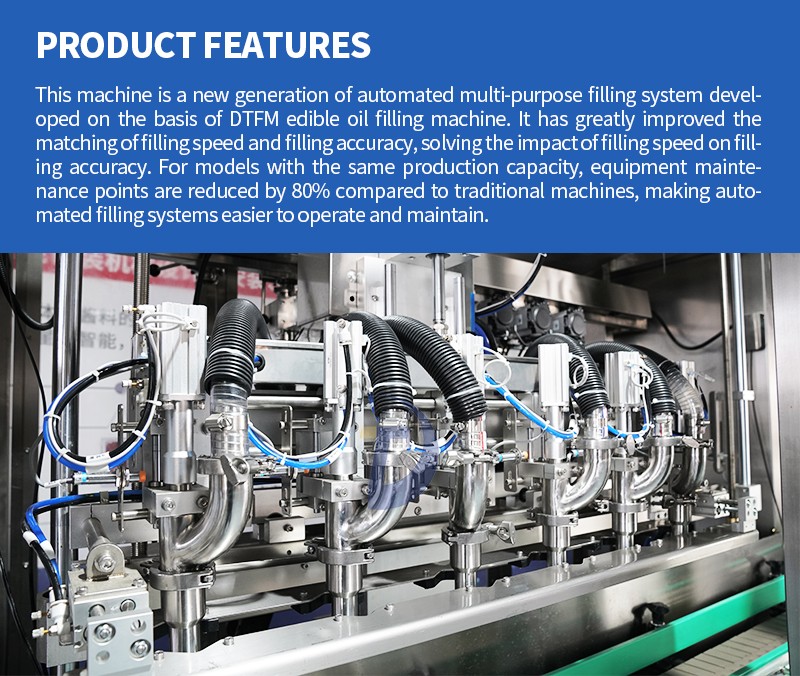

This machine is a new generation of automatic multi-purpose filling system developed on the basis of DTFM edible oil filling machine. It has greatly improved the matching of filling speed and filling accuracy, and solved the influence of filling speed on filling accuracy. With the same output model, the equipment inspection point is reduced by 80% compared with the traditional machine, making the automated filling system easier to use and maintain. This model can be used with Dongtai's tracking capping machine to break the traditional linear filling machine's catch-on filling, and truly realize the continuous bottle production in the filling line.

This machine is a new generation of automatic multi-purpose filling system developed on the basis of DTFM edible oil filling machine. It has greatly improved the matching of filling speed and filling accuracy, and solved the influence of filling speed on filling accuracy. With the same output model, the equipment inspection point is reduced by 80% compared with the traditional machine, making the automated filling system easier to use and maintain. This model can be used with Dongtai's tracking capping machine to break the traditional linear filling machine's catch-on filling, and truly realize the continuous bottle production in the filling line.

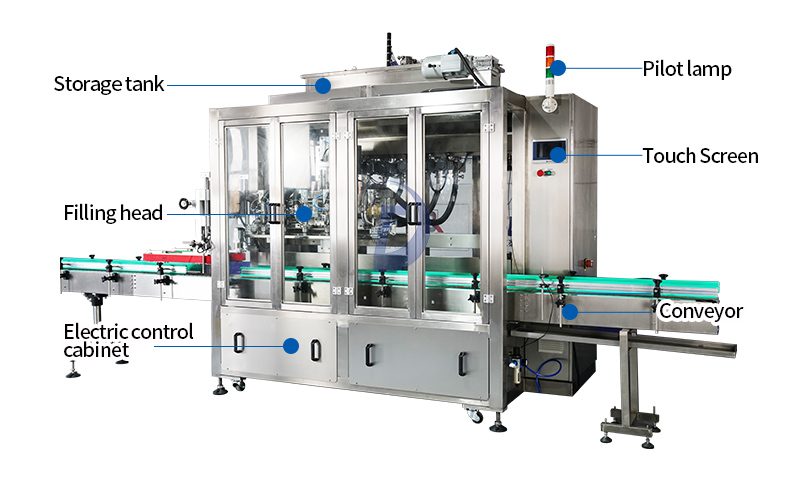

PLC intelligent control

PLC intelligent control, liquid crystal display, quantitative accuracy, to ensure that in the production process in strict accordance with the process of work, with overload clutch protection device, automatic shutdown alarm in the event of abnormal conditions.

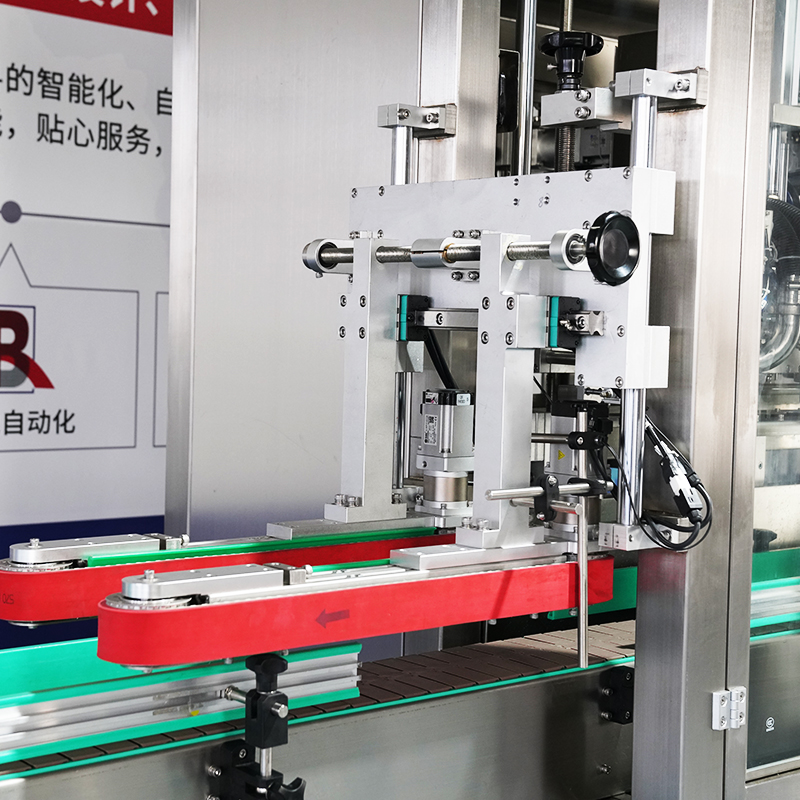

Tracking filling method

Break the traditional linear filling machine filling, truly realize the filling line continuous bottle production.

True air drip-proof device

The filling device is filled with thousands of edible oil, which is controlled by computer according to the capacity of intelligent filling. The tolerance is very small, avoid the phenomenon of overflow caused by uneven filling, and have good stability.

Accurate filling measurement

Accurate measurement, quantitative error of 2 ml higher than the measurement standard 50%, each filling head independent control

Switch, independent fine tuning, filling process can dynamically display the filling progress.