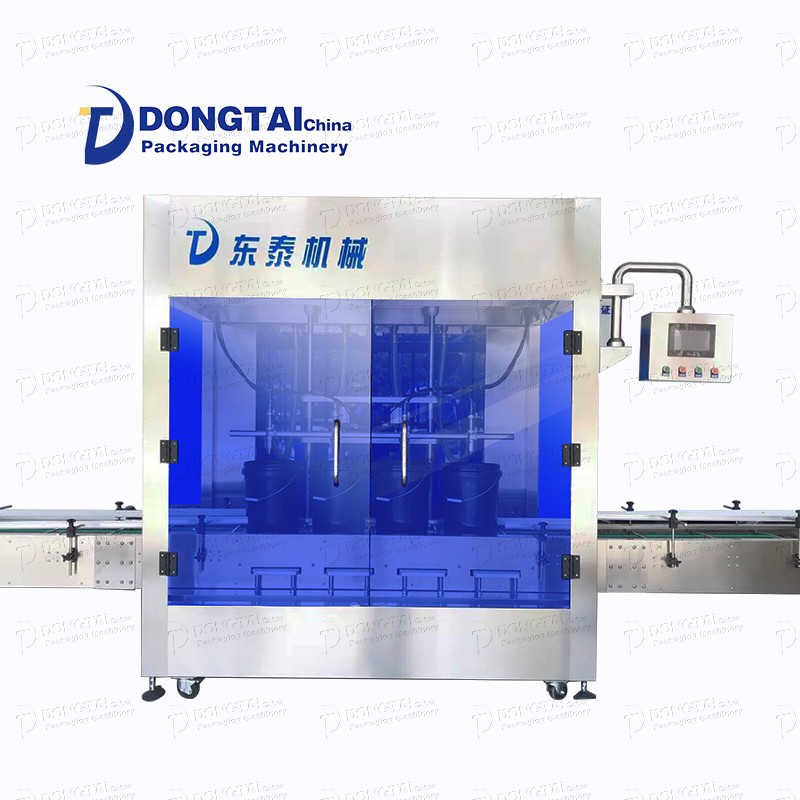

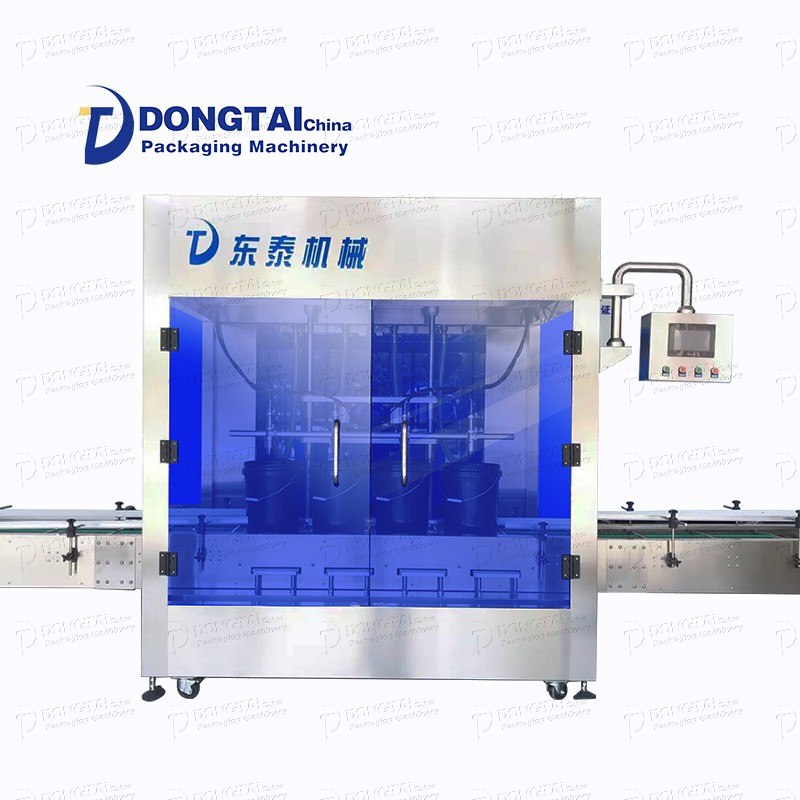

engine oil filling machine car oil filling machine lube oil filling machine Good quality

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

The engine oil filling machine is suitable for filling 4kg-25kg automotive products: lubricating oil, antifreeze, car urea and other liquids. Automatically complete a series of operations such as counting into the bottle, weighing and filling, and conveying out the bottle. It is especially suitable for quantitative filling of lubricating oil, liquid agent and edible oil. It is an ideal filling machine for food, medicine, cosmetics and fine chemical industries.

Product Uses

Parameter

Parameter

| Dimensions | 2200* 1350mm *1820mm |

| Number of filling heads | 4 |

| Applicable bottle type | customized according to bottle type |

| Barrel diameter | customized |

| Packing specification | 4-30L |

| Production capacity | 400-800 barrels/hour |

| Measurement error | ±0.1% |

| Equipped with power supply | 220V; 50Hz |

| Host power | 3KW |

| Equipped with air source | 0.55Mpa-0.65Mpa |

Product advantages:

Product advantages:

1. The engine oil filling machine weighing instrument panel is a special controller for quantitative packaging scales, with fast response speed, high precision and complete functions.

2. The load cell replaces the Toledo intrinsically safe sensor. The multi-layer medium is sealed and has strong anti-partial load capacity. It has the characteristics of dustproof, waterproof, explosion-proof, anti-button, and corrosion resistance. It meets the IP67 sealing standard.

3. The part contacting the material is 304L stainless steel and PTFE material, which is acid-resistant and corrosion-resistant. Special materials can be customized according to the nature of the material.

4. The flow of materials is controlled by the double-speed ball valve and the bottom valve of the spray gun. It is accurate and reliable. The user can adjust the speed of the filling speed through the dashboard keyboard.

5. All valves can close by themselves when the air pressure is insufficient and the goods are powered off.

6. engine oil filling machine Adopt unique hardware and software design, which can effectively prevent the material from dripping and ensure the cleaning of the filling equipment and packaging container.

6. engine oil filling machine Adopt unique hardware and software design, which can effectively prevent the material from dripping and ensure the cleaning of the filling equipment and packaging container.

7. This machine adopts temperature controller (PLC), touch screen operation control, easy to use and adjust.

8. Each filling head has a weighing and feedback system, which can set and adjust the filling amount of each head.

9. Adopting advanced sensor elements, no barrels and no filling, the host will automatically pressurize and alarm when the barrel is blocked.

10. The filling method is submerged, which can effectively reduce the generation of foam and satisfy the filling of materials with different characteristics.

11. Each through connection adopts quick assembly, replacement and disassembly and cleaning, and parts in contact with materials are made of high-quality stainless steel.

12. The structure of the whole machine meets the requirements of GMP, with stable performance, safety and environmental protection, and beautiful appearance.