Semi-automatic Hose Filling And Sealing Machine

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

(1) Semi-automatic Hose Filling And Sealing Machine adopts Taiwanese visual touch screen and delta PLC control system, convenient, intuitive and reliable non-contact operation, with compact structure and automatic tube feeding.The transmission is completely closed.

2. Semi-automatic Hose Filling And Sealing Machine is on the automatic system for tube feeding, marking filling, hot air sealing, code printing, trimming, pipe outlet, etc.Pneumatic feed is used for pipeline feeding, accurate and reliable.

3.The Semi-automatic Hose Filling And Sealing Machine is on an automatic pick-up with photoelectric inductance.Easy to adjust and remove.

Semi-automatic Hose Filling And Sealing Machine

Semi-automatic Hose Filling And Sealing Machine-Product description:

This Semi-automatic Hose Filling And Sealing Machine adopts full stainless steel, working process of the button control:put in tube manually, 10 work position with automatic rotary, quantitative filling, heat sealing, automatic cutting, printing and finished product output. All works with full cylinder stroke control, convenient to adjust filling quantity, the filling speed is adjustable.

This machine is suitable for all kinds of plastic and composite hose filling, sealing, date printing, cutting. Sealing appearance is beautiful, neat, fastness, high measuring accuracy, good stability. According to different materials, optional parts:hopper heating system, filling head with anti-pull function.

Semi-automatic Hose Filling And Sealing Machine-Product parameters:

Power supply | ~220V±10%50HZ |

Power | 400W*2 |

Pressure | 0.6-0.8(MPA) |

Gas consumption | <30(dm3/min) |

Filling volume | 30-200(ml) |

Filling speed | 20-30 pieces/min |

Filling precision | <2% |

| Dimension | 1230mm*700mm*1400mm |

Weight | 600(kg) |

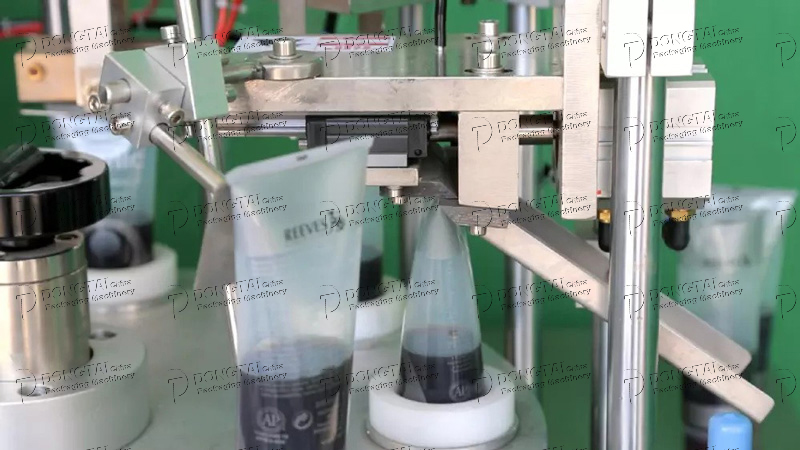

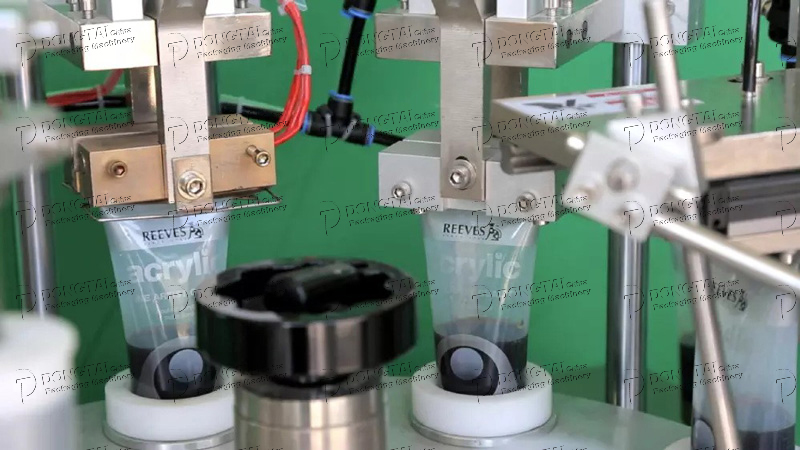

Semi-automatic Hose Filling And Sealing Machine-Product details picture and description:

A. This filling and sealing machine has simple structure, reasonable and easy to understand, and high accuracy.

B. By the magnetic reed switch can control cylinder stroke, you can adjust the amount of filling.

To complete the supply pipe, pipe washing by pneumatic method, accurate and reliable action.

E. Intelligent temperature control and cooling system, make the operation simple, convenient adjustment.

with a number of memory and equiped with a quantitative shutdown device.

F. Materials in contact part of our tube filling and sealing machine adopts 316L stainless steel manufacturing, clean, sanitary, fully meet the requirement of pharmaceutical production GMP.

Semi-automatic Hose Filling And Sealing Machine-The finished product to show: