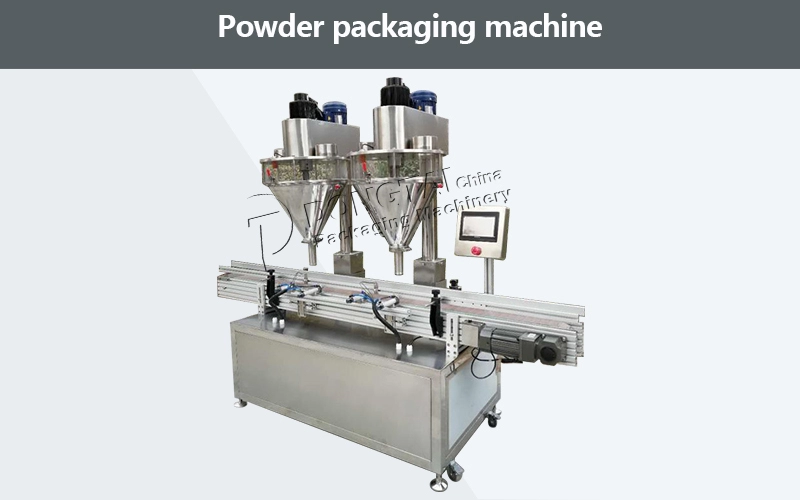

Semi-automatic powder filling machine, coffee powder/milk powder/ginger powder filling machine

- DONG TAI

- CHINA

- 15 WORKING DAYS

- 1000 SETS/YEAR

1. The combination of semi-automatic powder filling machine and bottle opener, capping machine and labeling machine can form a complete filling line;

2. Coffee powder filling machine is economical and cost-effective;

3. The ginger powder filling machine automatically positions and fills, saving time and effort.

Semi-automatic powder filling machine, coffee powder/milk powder/ginger powder filling machine

PRODUCT INTRUDUCTION

Semi-automatic filling machine is an economical powder and small particle automatic filling machine, which can complete automatic positioning, filling and metering of bottles. It consists of a filling head, a connecting belt and a positioning device. (Or stepping) motor, PLC and touch screen control, easy operation and high stability. It can be combined with bottle opener, capping machine and labeling machine to form a complete filling line.

PRODUCT FEATURES

- Stainless steel parts

The filling sealing machine automatic has a wide range of applications: powder and granular materials with certain fluidity can be packaged. Photoelectric switch control, only need manual bagging. The pocket is clean and easy to seal. The parts in contact with the materials are made of stainless steel, which is easy to clean and prevent cross contamination

The filling sealing machine automatic has a wide range of applications: powder and granular materials with certain fluidity can be packaged. Photoelectric switch control, only need manual bagging. The pocket is clean and easy to seal. The parts in contact with the materials are made of stainless steel, which is easy to clean and prevent cross contamination

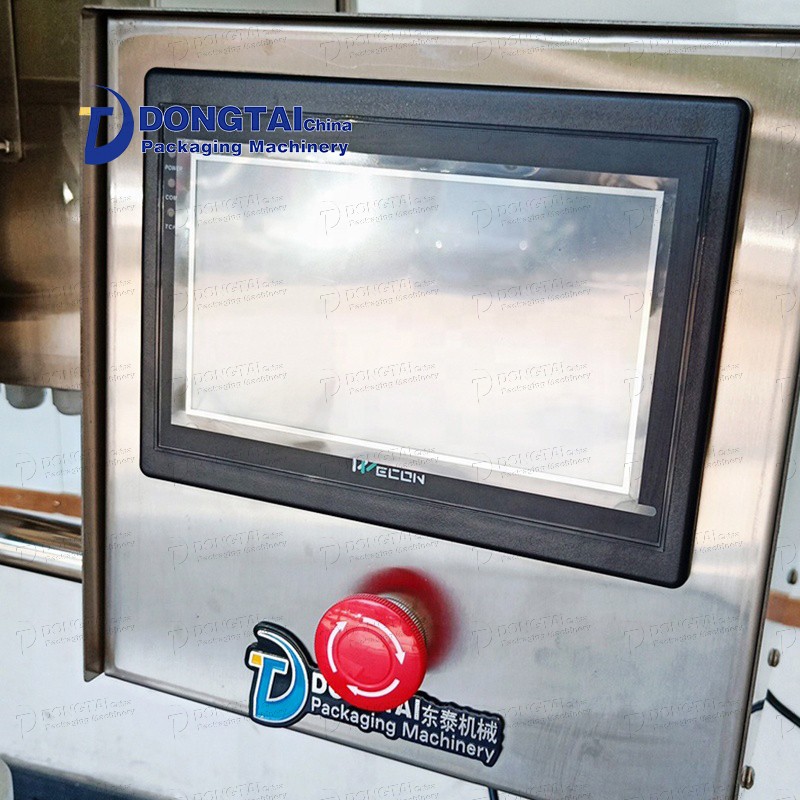

- PLC touch screen

Adopting international and domestic advanced technology, PLC and touch screen control, the semi automatic powder filling machine is easy to operate, high stability, optical fiber sensor control, microcomputer text display and touch manual interface operation.

Adopting international and domestic advanced technology, PLC and touch screen control, the semi automatic powder filling machine is easy to operate, high stability, optical fiber sensor control, microcomputer text display and touch manual interface operation. - Screw rod

Servo (or stepping) motor drives the screw, accurate positioning, speed setting, replacement of screw attachments, suitable for various materials from ultra-fine powder to small particles. After the material flow, the filling machine powder is equipped with a centrifugal device to ensure accuracy. Dust material outlet can adopt dust suction device to absorb spray-proof dust.

MAIN PARAMETER

product name | powder filling machine | |

Metering method | weighing measurement | screw quantification |

Package weight | 50 g -5 kg (replacement of spiral accessories) | 1-500 grams (replace the spiral attachment) |

Packing accuracy | ≤±0.3% | ≤ ± 1% |

Filling speed | 5-25 bottles / min | 20-40 bottles / min |

Power | 3P AC208 ~ 415V 50/60Hz | 3P AC208 ~ 415V 50/60Hz |

Engine power | 2.3kW | 2.3kW |

Weight | 350KG | 350KG |

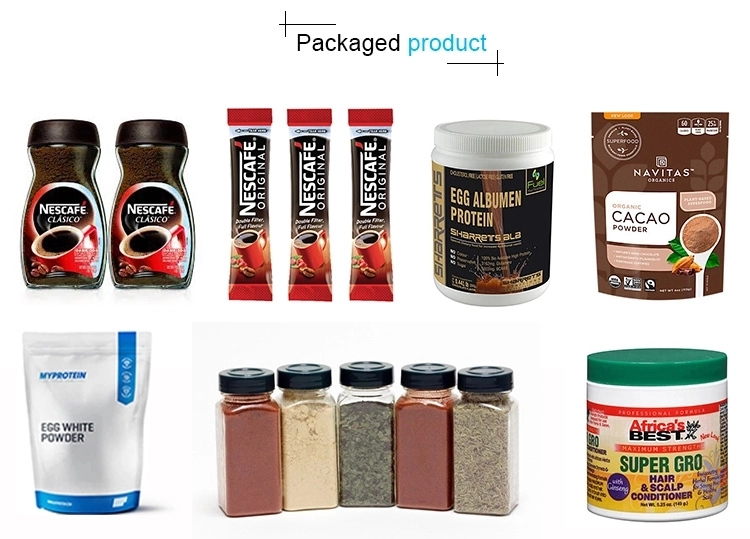

powder filling machine---Suitable for material display:

FAQ: