5-30l oil filling machine automatic engine oil filling machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

The engine oil filling machine is suitable for filling the weight of 10kg-30kg of fluid. Automatically complete a series of operations such as counting into the bottle, weighing and filling, and delivering the bottle

Make. Especially suitable for quantitative filling of liquid agent and paste, it is an ideal packaging machine for food, medicine, cosmetics and fine chemical industries.

5-30l oil filling machine automatic engine oil filling machine

Product Description

Product Description

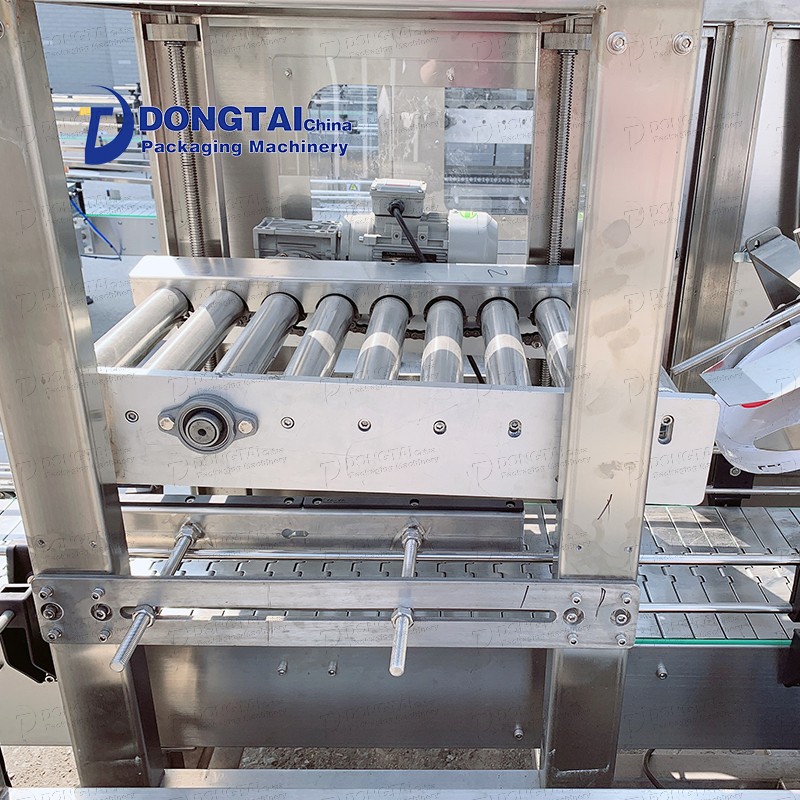

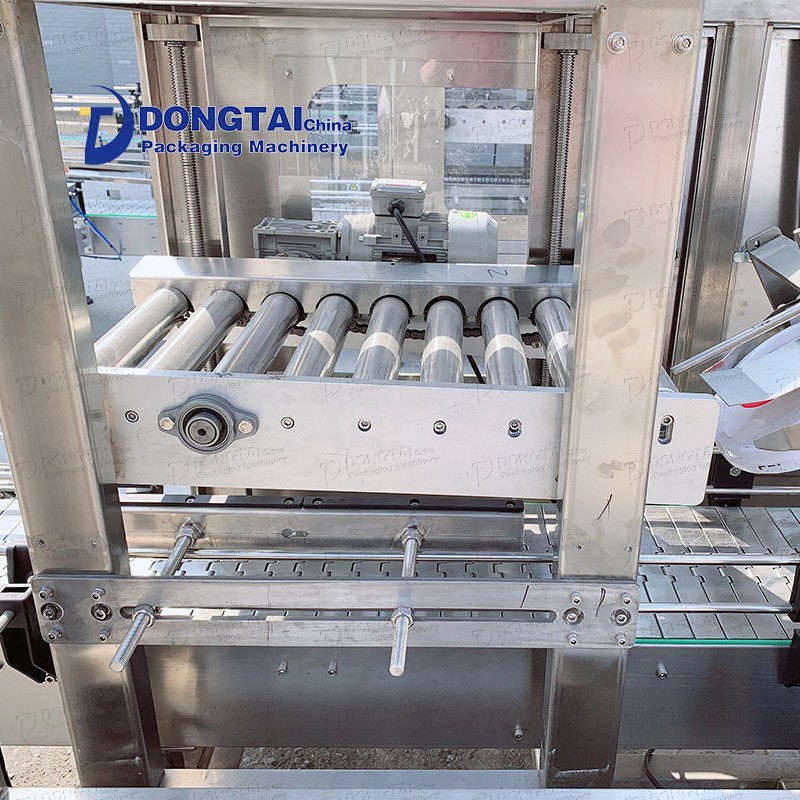

This machine adopts programmable controller (PLC), high-speed industrial control configuration software for real-time monitoring and control, easy to use and adjust. According to GMP standard

Manufactured according to quasi-requirements, the connection of each pipeline is quick-installed, easy to disassemble and clean, and parts in contact with materials and exposed parts are made of high-quality stainless steel

manufacture. The whole machine is safe, environmentally friendly, safe, beautiful, and can work in various environments.

Product Uses

| Product name | engine oil filling machine |

| Barrel diameter | Customized |

| Bottle type | Customized |

| Capacity | 5-30L |

| Production capacity | 250 barrels/hour |

| Suitable for | Motor oil |

| Control | plc |

| monitor rate | 3kw |

| Measurement error | ±0.1% |

| Dimensions | 2200*1350mm*1820mm |

Full automatic capping machine:

System: Electronic-pneumatic/computer (PLC) control

Speed: 10-12 times/minute

Operation: manually put the cover into the silo, the machine automatically positions, automatically falls the cover, automatically hangs the cover, automatically rolls the cover

Conveying: automatic conveyor belt

Frame: stainless steel frame material

Cover warehouse: replace cover type, need to replace cover warehouse

Main functional characteristics and technical description:

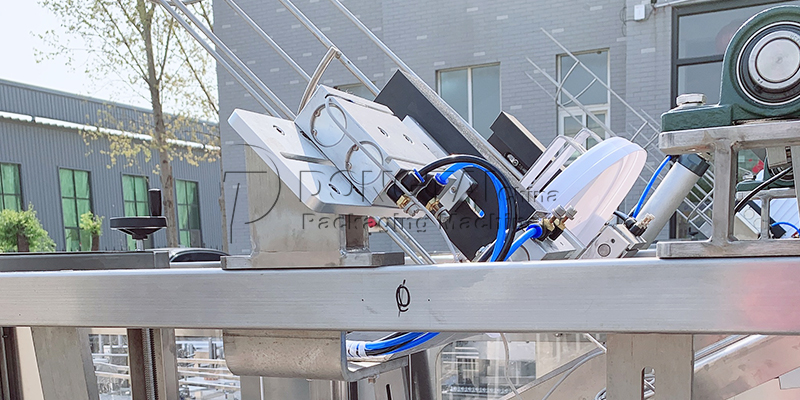

1) "Automatic suction cover" automatic control system:

Multi-point detection of the whole machine, monitoring the position of falling cover through photoelectric sensor

2) "Photoelectric sensor, mechatronics cover drop" automatic control system:

2 sets of cylinders are used to peel off the barrel lid. After the suction cup automatically sucks the lid, the lid automatically slides along the cover channel to the automatically filled area of the filled barrel.

When the cover is full, the suction cup does not work. The barrel behind the lid is automatically rolled.

Labeling Machine-Product Introduction

Advanced and friendly human-machine interface system, simple and intuitive operation, complete functions, and rich online help functions

The unique three-point positioning of the bottle body avoids the label skew caused by the uneven bottom of the bottle and the vertical error of the bottle body when the ordinary vertical labeling machine is labeling.

Labeling is more accurate, beautiful and easy to apply

The machine structure is simple and compact, easy to operate and maintain

Adopt well-known brand motor drive, stable and reliable delivery speed

Using well-known brand pneumatic components, durable

3. Product Features

intelligent control

The whole machine adopts mature PLC control system, which makes the whole machine run stably, high-speed and more stable positioning mechanism, and unique three-point positioning of the bottle body.

Avoid the skew of labeling caused by the uneven bottom of the bottle and the vertical error of the bottle body during the labeling by the ordinary vertical labeling machine, so that the labeling is more accurate, beautiful, and easy to apply

The operating system adopts touch screen control, easy to operate, practical and high efficiency

Labeling speed, conveying speed, turntable positioning speed can realize stepless speed regulation, adjust as needed

Scope of application

Suitable for circular labeling of round objects

Three-point positioning of the bottle body makes the label attachment more accurate and firm

The rear section can be optionally connected to the assembly line, and can also be equipped with a receiving turntable to facilitate the collection, sorting and packaging of the finished product

Coding system

Optional configuration (coding machine) can print the production date and batch number online, reduce bottle packaging process, and improve production efficiency

Advanced technology (pneumatic/electric) coder system, the printed handwriting is clear, fast and stable

Air source for thermal coding machine: 5 kg/cm2

Labeling quality

Using three-point positioning turntable, labeling is faster, more accurate, more stable, smoother, wrinkle-free, greatly improving packaging quality