Automatic bottle liquid piston filling machine for perfume, oral Liquid Essential Oil Solvent

- dongtai

- china

- 7days

- 100

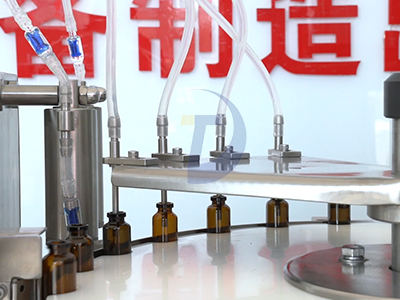

Integrated the filling and capping in one compact machine, it can finish the following procedure automatically, filling, caploading, capping and bottle existing, etc. the machine is featured with accurate filling, smooth working, and comply to GMP standard. It is widely used in healthcare, food, chemical,daily chemical, cosmetics industries.

Integrated the filling and capping in one compact machine, it can finish the following procedure automatically, filling, caploading, capping and bottle existing, etc. the machine is featured with accurate filling, smooth working, and comply to GMP standard. It is widely used in healthcare, food, chemical,daily chemical, cosmetics industries.

Main Features

1. The equipment operation interface is touch screen, the whole machine is controlled by PLC, and the operation is simple and reliable.

2. The linear bearing used in the table of the filling machine is German Igus oil-free bearing to avoid product pollution.

3. Filling by piston ensures the high accuracy, anti-dripping, foaming or splashing.

4. The signals of cylinder operation are detected by respective photoelectric signals and then controlled by PLC output.

5. The operation mode is generally divided into manual mode and automatic mode.

6. All parts in contact with the bottle and liquid medicine are made of high-quality AISI304 or AISI316 stainless steel and

meeting GMP requirements.

Stainless steel material

The product is strictly delivered stainless pot material, with high egg degree, not easy to cross shape, solid country practical, the surface is bright and clean

Chinese subtitle control is easy

Large screen panel, clearly visible, accurate value, one click to talk, convenient and fast Material transfer stabilizationMaterial conveying pipes are all 304 stainless, male first road, born warm Easy to decompose, long use time

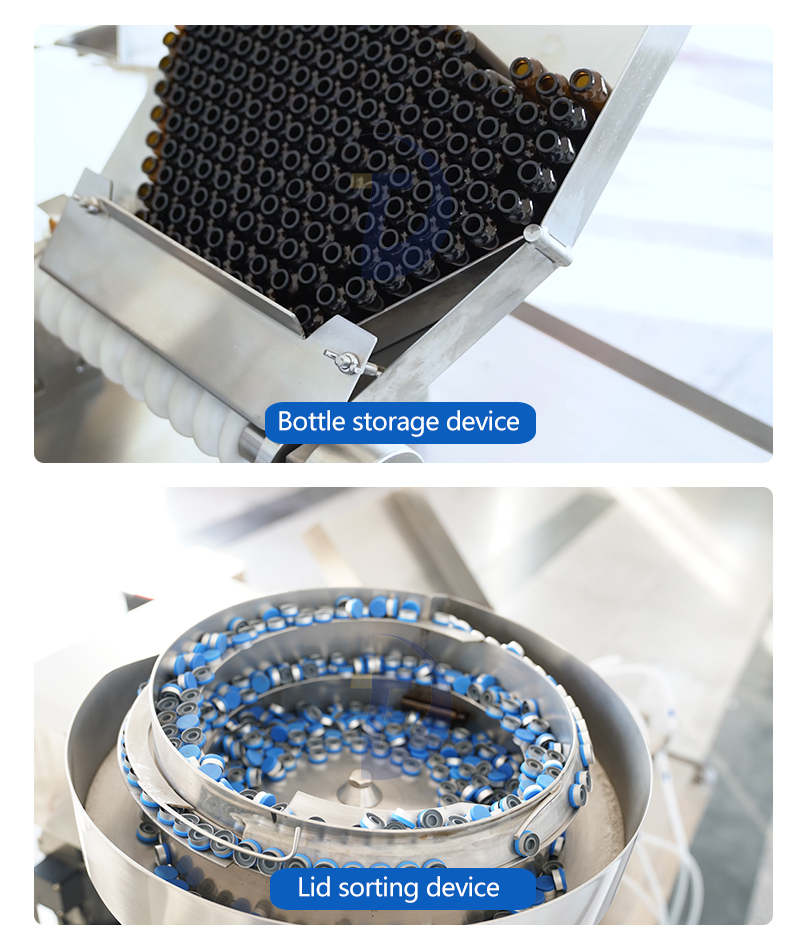

Automatic capping

The left is equipped with automatic capping device, and the right measuring mechanical arm is responsible for capping, with reasonable and compact layout.

The capping force is uniform

Continuous single-blade or three-blade capping, capping force uniform and soft, wide versatility