Automatic capping machine for soy sauce vinegar

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

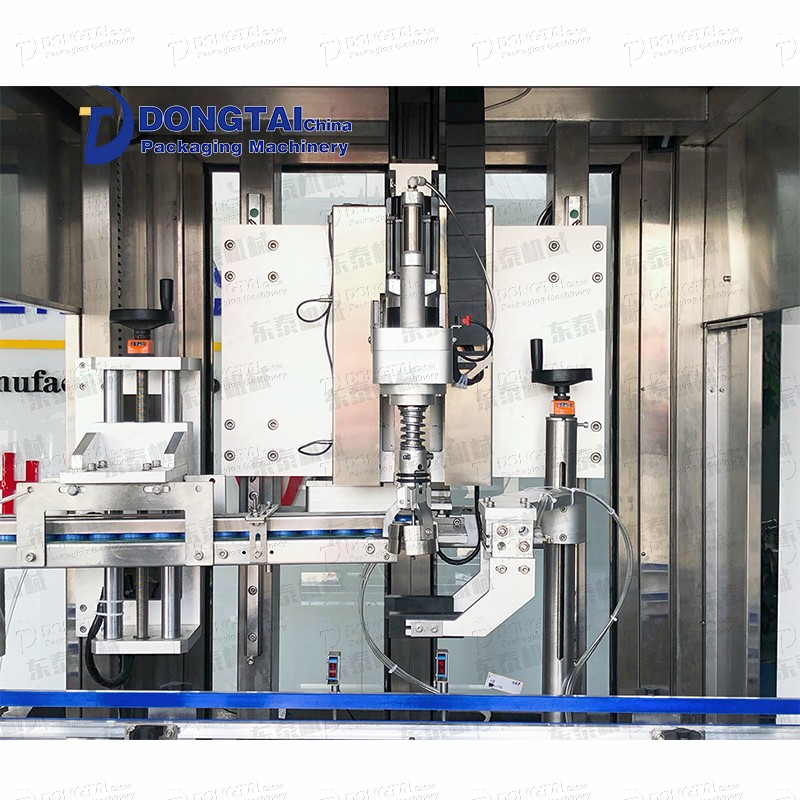

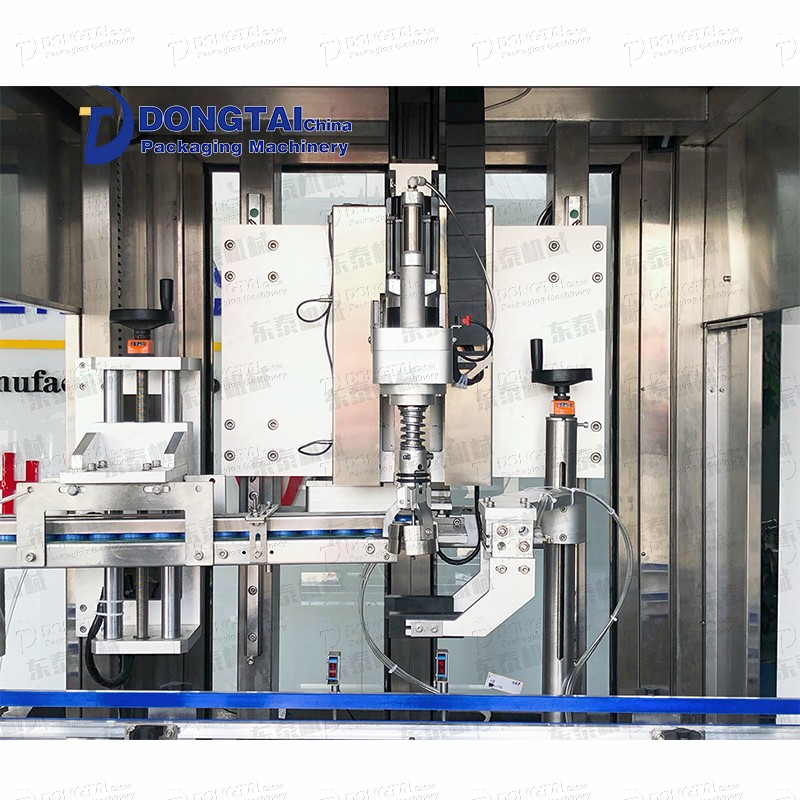

The capping machine is mainly suitable for pharmaceutical, food, chemical, daily chemical and other industries, and is an ideal supporting equipment for automated production lines. No vibration, no noise; the bottle enters straight, continuous capping, efficient and fast (the capping speed is 2-3 times that of ordinary capping); automatic failure shutdown and automatic shutdown system without cap, safer, suitable for various Automatic capping of bottle mouth of specifications.

Automatic capping machine for soy sauce vinegar

Plastic cap capping machine---Features:

1. Applicable to various plastic covers and metal covers, with strong adaptability;

2. The automatic lid-up device adopts pure manual polishing, with high production precision, stable upper lid and reliable lower lid.

3. Low noise and low failure rate to ensure the safety and reliability of the equipment;

4. The whole machine is made of stainless steel, beautiful in appearance, and meets food hygiene quality requirements.

Capping machine---Detailed description:

1. The latest capping machine adopts capping and does not damage the cap. Fast, safe, stable, high sealing efficiency.

Automatic cap screwing machine for plastic bottlesAutomatic bottle capping machine for plastic bottles

2. The capping machine is a fully automatic capping machine. It is used with capping machine. After the cap is full, photoelectric detection will be carried out to control the capping machine to stop automatically. When the number of bottle caps is insufficient, automatic capping machine. There are two anti-cap devices in the bottle cap descrambler to ensure that the unscrambled bottle cap is down 100%.

Automatic cap screwing machine

3. The cover remover slides the cover into the cover removal device through the cover drop slot, and its width can be adjusted by the handwheel according to the size of the cover. The lid drop slot is equipped with light solder, which can detect the fullness of the lid and the number of lids for automatic control.

Automatic cap screwing machine

4. To change the specifications, you only need to replace the covers and grab heads of different specifications, and you can switch between different products in 2 minutes.

FAQ

1. What is your delivery time?

Answer: It usually takes around 30 days to manufacture the whole production line. For emergent needs of special parts, the process could be shortened.

2. What is the warranty and how is the after-sale service?

Answer: We provide one-year warranty which does not include easily damaged spare parts, such as heaters, belts, etc. Technicians will guide you to install, test machines, and provide free training to your staff in terms of operating and maintaining the machines. Operating manuals will also be sent with machine or by email.

3. Can you arrange technicians for overseas debugging?

Answer: Yes, we can provide services as needed exclude visa fees, round-trip air tickets, and accommodation. We can also arrange your technicians to study in our factory before shipment.

4. Is the machine available with 415V/380V /220V/110V?

Answer: We provide solutions and converter to different power sources and different plug bases for customers from all over the world.

5. Are you a manufacturer or trade company?

Answer: We are a manufacturer in filling and packaging machine field more than a decade. With experienced engineer and technician team, we can provide the best solution to your requirement. If you are interested, we can arrange factory tour for you.

6. Do you have any certification?

Answer: We are CE and ISO9001 certified company.