Small Bottle Powder Filling Machine

- DONGTAI

- SHANDONG

- 15 WORKING DAYS

- 1000 SETS/YEAR

Features of Small Bottle Powder Filling Machine:

1. The contact parts of materials are made of 316 stainless steel, meeting GMP requirements.

2 Small Bottle Powder Filling Machine adopts anti-drip Filling device.

3. Pneumatic components are controlled by PLC (German FESTO) and AirTac (Taiwan) with touch screen Settings.

4. Small Bottle Powder Filling Machine seals are made of silicone rubber (resistant to wear, high temperature, acid and alkali, and corrosion) and fluororubber (resistant to wear, strong acid and alkali, and strong corrosion).

5. This device can remove the long leather tube from the outlet and move the filling at will, which can meet the unlimited (arbitrarily adjustable) filling capacity requirements of more than 1ml.

6. The liquid filling machine is not limited by the filling equipment and is a reliable and durable liquid filling machine.

Small Bottle Powder Filling Machine

Small Bottle Powder Filling Machine-Product description:

Small Bottle Powder Filling Machine The machine is an economical powder and small particle automatic filling machine, which can complete the automatic positioning, filling and metering of the bottle. It consists of a filling head, a connecting belt and a positioning device. Or stepper) motor, PLC and touch screen control, easy to operate, high stability. It can be combined with bottle unscrambler, capping machine and labeling machine to form a complete filling line. Suitable for packaging powder and small granular materials, such as powder, small granules, veterinary drugs, glucose, condiments, solid beverages, toner, talcum powder, pesticides, etc.

Characteristics:

1.Small Bottle Powder Filling Machine The outer appearance of the whole machine is made of stainless steel except the motor; the combined transparent material box can be easily removed and washed without tools.

2.Servo (or stepper) motor drive screw, which has the advantages of not easy to wear, accurate positioning, speed setting, and stable performance.

3.Small Bottle Powder Filling Machine It adopts PLC control and has the advantages of stable operation, anti-interference and high weighing accuracy.

4.Small Bottle Powder Filling Machine Chinese and English touch screen clearly shows the working status, operation instructions, fault status and production statistics, etc. The operation is simple and intuitive.

5.Small Bottle Powder Filling Machine Replace the spiral attachment to adapt to a variety of materials, from ultrafine powder to small particles.After the flow of good material, the centrifugal device is installed to ensure the accuracy, and for the dusty material outlet, the dust suction device can be installed to absorb the anti-spray dust.

Small Bottle Powder Filling Machine-Product parameters:

Metering method | weighing measurement | screw quantification |

Package weight | 50 g -5 kg (replacement of spiral accessories) | 1-500 grams (replace the spiral attachment) |

Packing accuracy | ≤±0.3% | ≤ ± 1% |

Filling speed | 5-25 bottles / min. | 20-40 bottles / min. |

Power | 3P AC208 ~ 415V 50/60Hz | 3P AC208 ~ 415V 50/60Hz |

| Engine power | 2.3kW | 2.3kW |

| Weight | 350KG | 350KG |

Small Bottle Powder Filling Machine-Product details picture and description:

NO.1

Small Bottle Powder Filling Machine

HMI

Intelligent system control

NO.2

Automatic photoelectric sensor for raw materials

Automatic detection

Automatic feeding

-INTELLIGENT OPERATION-

NO.3

Buffer airbag

When filling materials

It can buffer the extrusion

of air in the hopper

NO.4

Open door construction

Stainless steel screw,precision machining,

stable and reliable,high precision.

NO.5

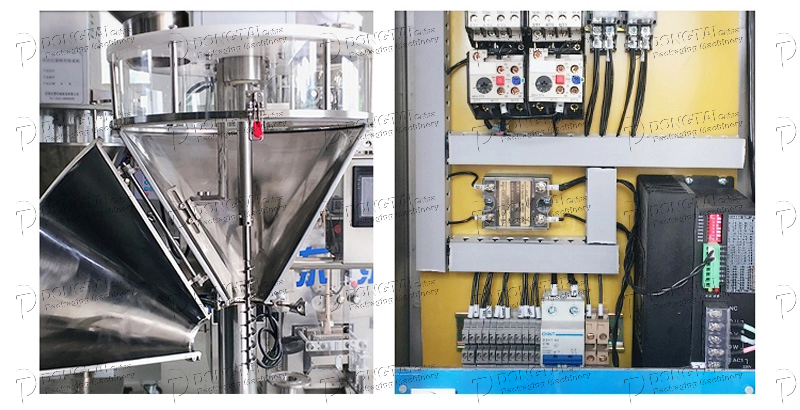

Electronic control module

Maintenance is convenient

NO.6

convenient material cleaning

quick screw replacement

NO.7

Add a funnel-type feeder to

prevent material spillage

NO.8

Make the machine working

performance more stable

NO.9

Stabilize the bottle body to prevent the bottle

from tilting and ensure accurate cutting

Small Bottle Powder Filling Machine-The finished product to show: